Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

All metal throat

I wanted to share my troubles replacing the ptfe lined throat and hot end. I also replaced the Bowden gear with a hardened steel version as well so I can reach higher temps for nylon, polycarbonate and carbon fiber...

In the images below you can see the longer throat with the plastic lining and the shorter one with the all metal construction. Yes, I did damage it good trying to remove the old. I am never going back so it doesn’t bother me...

Not going to lie it was a giant pain in the arse. Turns out the e3d nozzle has an m7.1 thread in the heat sink where Jg has an m6x1 still. So I had to drill and tap a new hole for that. No issue.

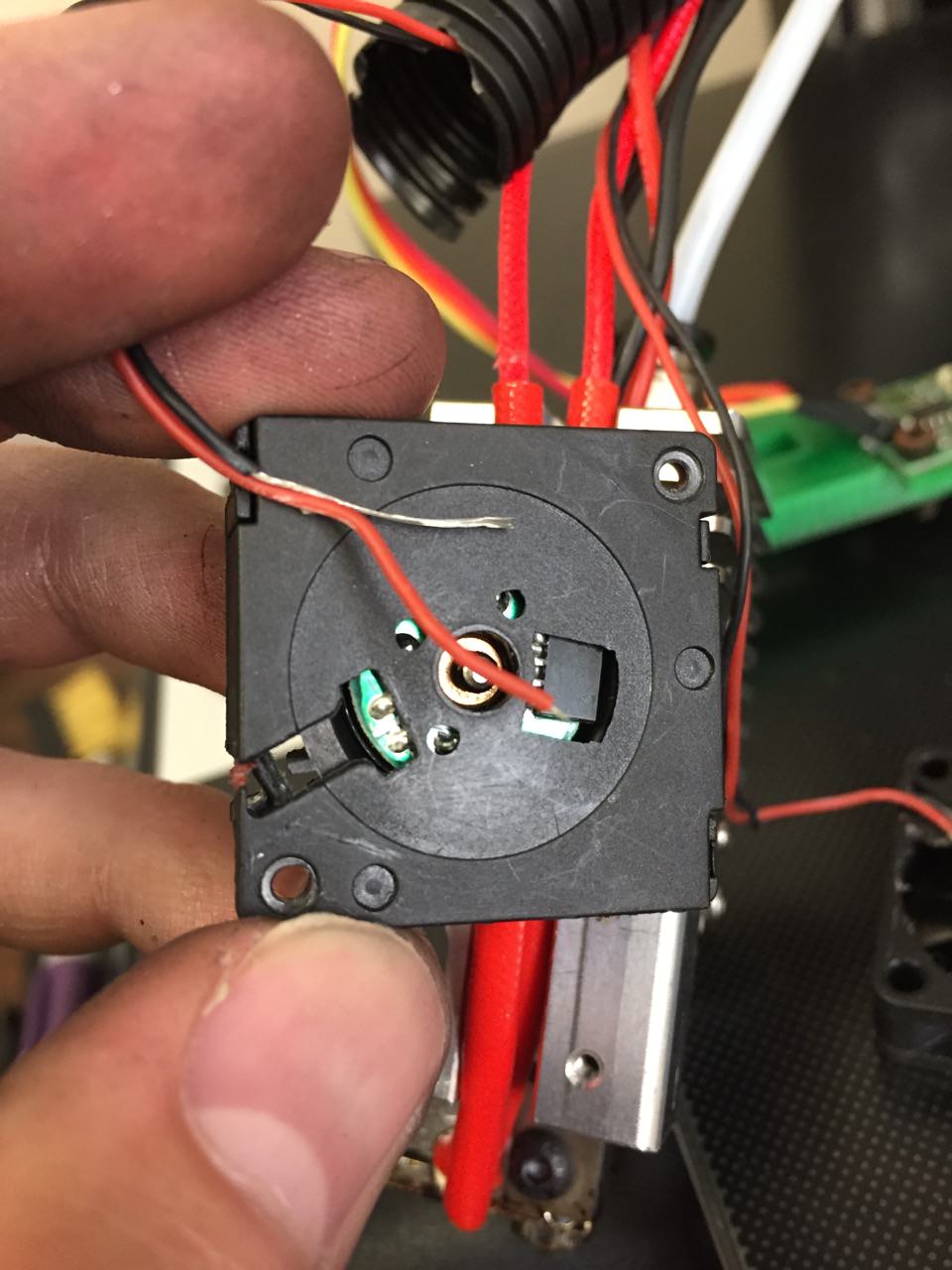

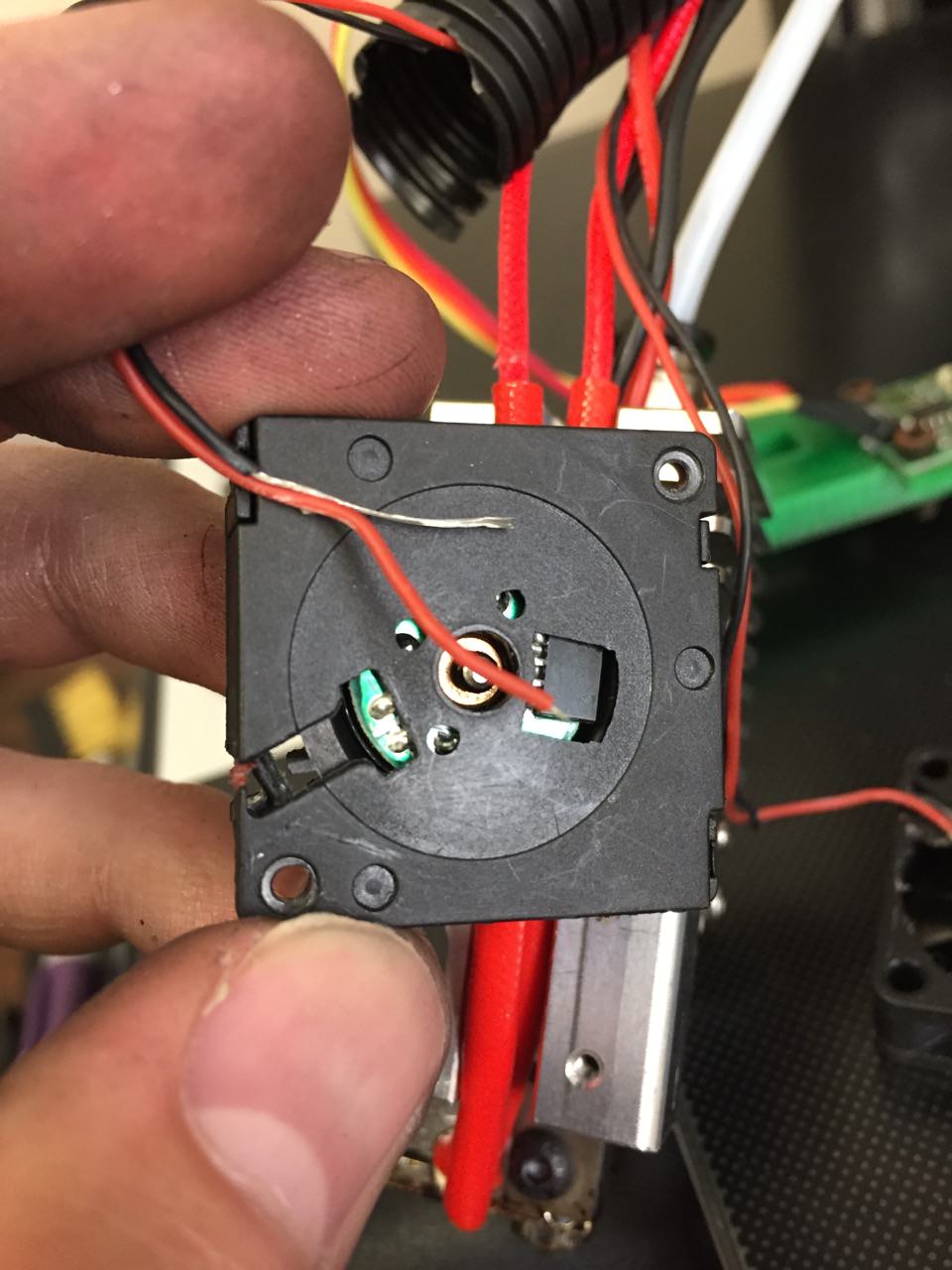

Then the wire pulled off from the heat sink fan which is not a very easy solder job, let me tell you. Then I had trouble getting the gt belts tight in the block but finally got it.

you might also notice the length is much different. My nozzle is now much further from the bed but I do have automatic bed leveling so I just had to adjust my -z settings, and by adjust I mean double it from -2 to -4...

Now all I need is to remove the 250 Celsius limit in marlin. Although I’ve noticed simplify 3d overrides this limit if you set it higher it would still be nice to preheat bed and extruder at same times.

In the images below you can see the longer throat with the plastic lining and the shorter one with the all metal construction. Yes, I did damage it good trying to remove the old. I am never going back so it doesn’t bother me...

Not going to lie it was a giant pain in the arse. Turns out the e3d nozzle has an m7.1 thread in the heat sink where Jg has an m6x1 still. So I had to drill and tap a new hole for that. No issue.

Then the wire pulled off from the heat sink fan which is not a very easy solder job, let me tell you. Then I had trouble getting the gt belts tight in the block but finally got it.

you might also notice the length is much different. My nozzle is now much further from the bed but I do have automatic bed leveling so I just had to adjust my -z settings, and by adjust I mean double it from -2 to -4...

Now all I need is to remove the 250 Celsius limit in marlin. Although I’ve noticed simplify 3d overrides this limit if you set it higher it would still be nice to preheat bed and extruder at same times.

Thanked by 1Samuel Pinches

Comments

now that you’ve got an all metal hotend it is easy to increase the max temp limit - this is in configuration.h , you can just raise the limit and reflash.

Also ordered a larger blower fan to upgrade, the soldered wire probably won’t last forever....

The important detail regarding the TMC2XXX is that even if you have software control setup, you still are limited by the current set by the potentiometer - so that may need to be turned up, or it may become limiting.

https://store.micro-swiss.com/collections/spare-parts/products/thermal-tube-upgrade-for-makerbot-replicator-1-2

Have you installed the micro swiss throat on your printer? I would like to do that on my A5 so I can print at higher temperatures. Are there any tips and tricks you can pass along about this swap.

Keep in mind that the max. print temp. is 250-255 on the A5 so if you want to be most times in that range, think about a change to the E3D high temp. variant with the PT100.

In generell, the change is like a change to a other PTFE throat, there will be nothing special.

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!