Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

GOODBYE MRS. BOWDEN

philwald1184

Posts: 28🌟 Super Member 🌟

philwald1184

Posts: 28🌟 Super Member 🌟

Basically the only part I needed was a 8x1 steel nipple about 7/8" long. Plus extent the extruder wires...

Basically the only part I needed was a 8x1 steel nipple about 7/8" long. Plus extent the extruder wires...I'm getting better and smoother prints now and no more changing bowden fitting.

But I'm stilling having that one issue of not extruding at start points. I've done alot of research and stumbled upon the lin-advance setting in marlin. An article I read claimed the k factor in lin-advance should be higher for bowden setups and lowered for direct drives. The costume firmware has the k value at 75. I've been everywhere from 2-130 and dont see much of a differece.

Samuel Pinches? Would you be able to recommend anyone that could weigh in on this issue. I really like this setup but just can't figure out why its not extruding correctly at start points over 3" apart.

Thanks in advance!

Post edited by philwald1184 on

Comments

! I'm heading to bed, I'll reply tomorrow!

Perhaps you could try a test print - like two simple cylinders, far enough apart to cause the issue?

Ill check the voltage on extruder driver again and if its not that ill take extruder off and check everything again. I guess I assumed it might have somthing to do with the firmware being it was setup for a bowden system .

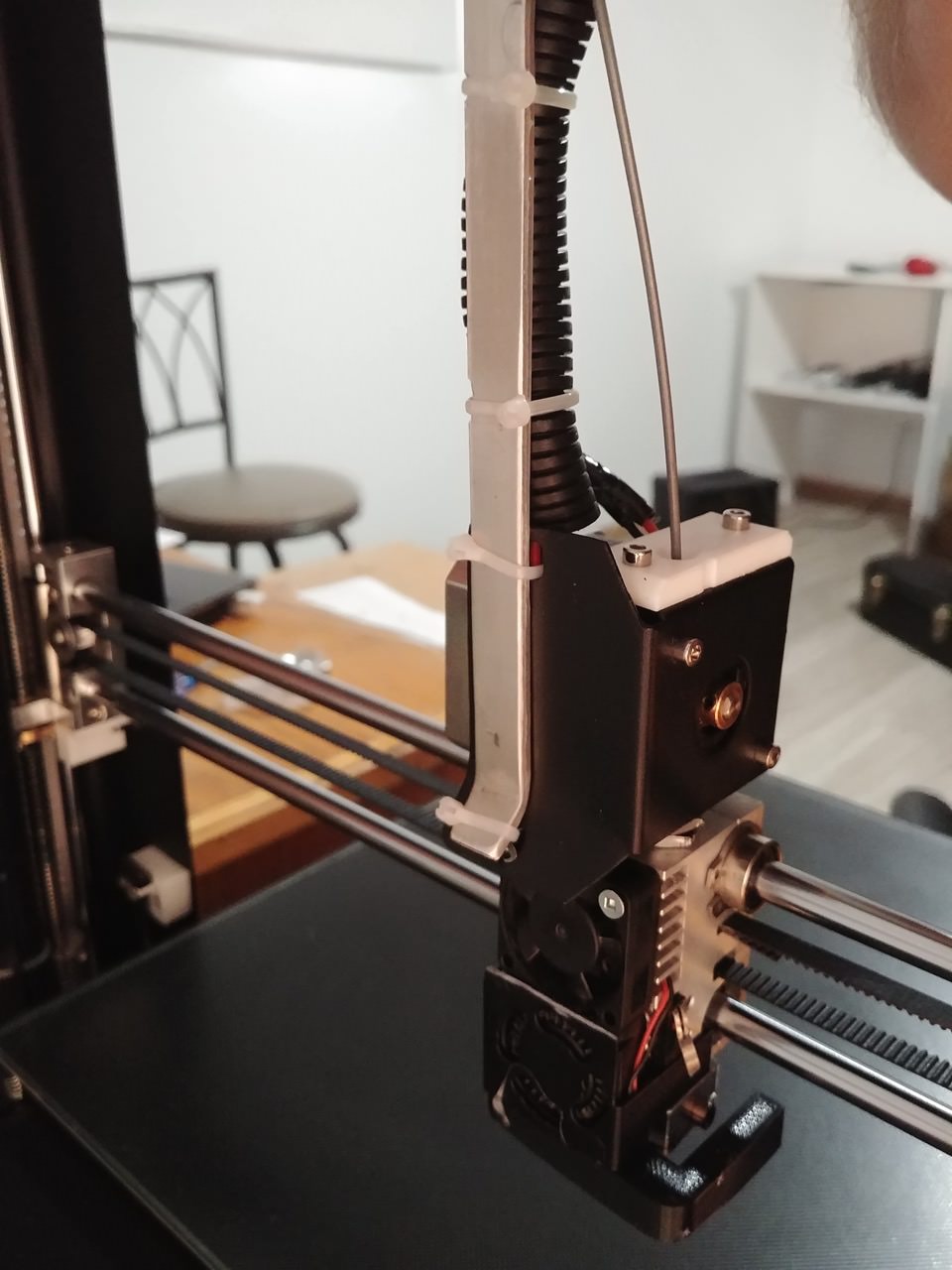

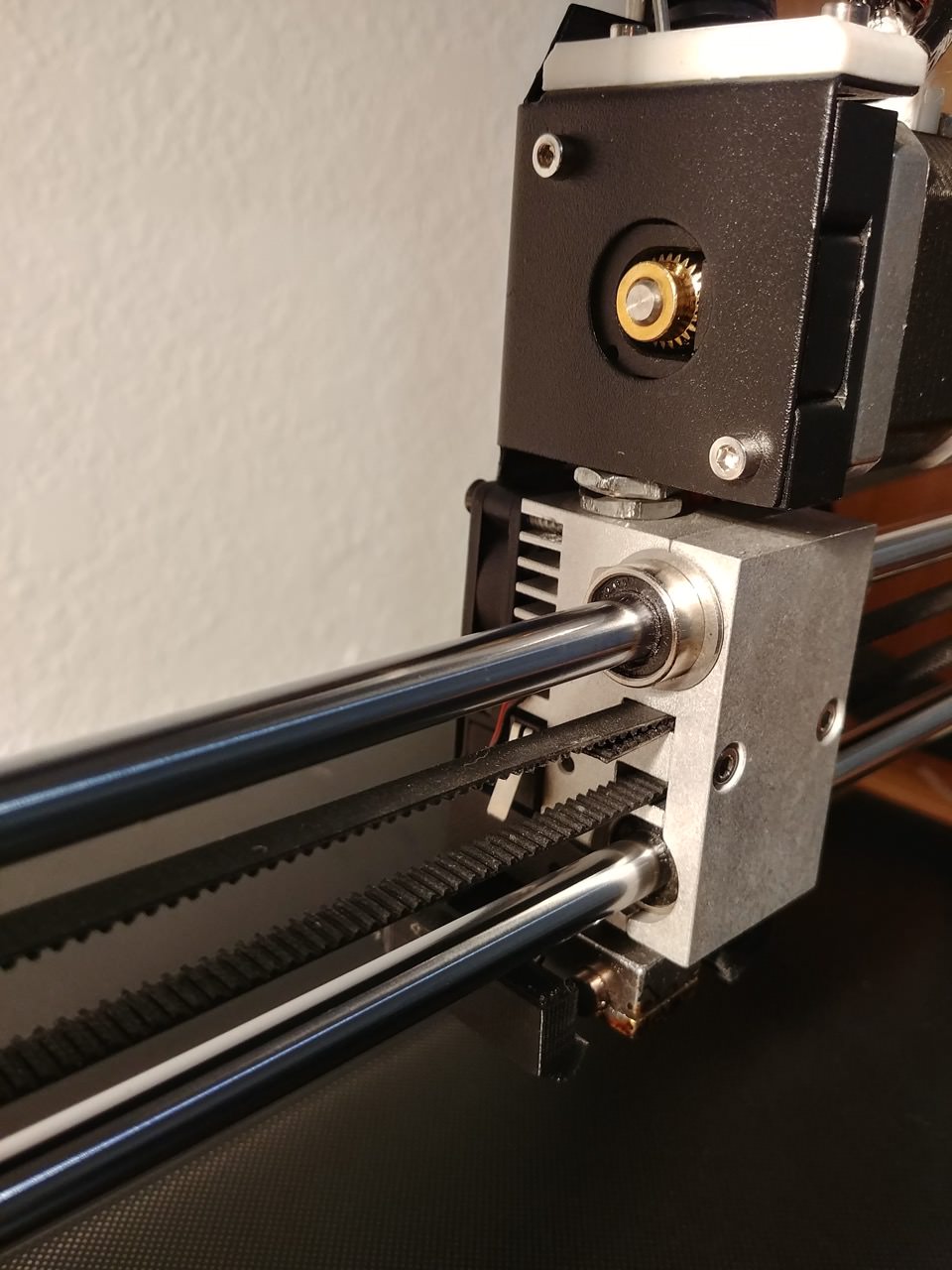

The nuts you see in between here are just a couple thin nuts I put in there in case I needed to tighten it up in a certain position but as it happens they weren't really needed.

If you drill a 4mm or 5/32 hole into it you can insert a piece of PTFE tube through it and have it extent further down towards the hot end (about 1 1/2" ) and also upwards (about 1/4") and I then glued it into my fitting so it wouldn't get dragged up or down.

I did however want a small gap to have the wires run underneath stepper motor but if you have a 7/8" long fitting then it'll tighten itself before closing that gap. You can see the wires here...

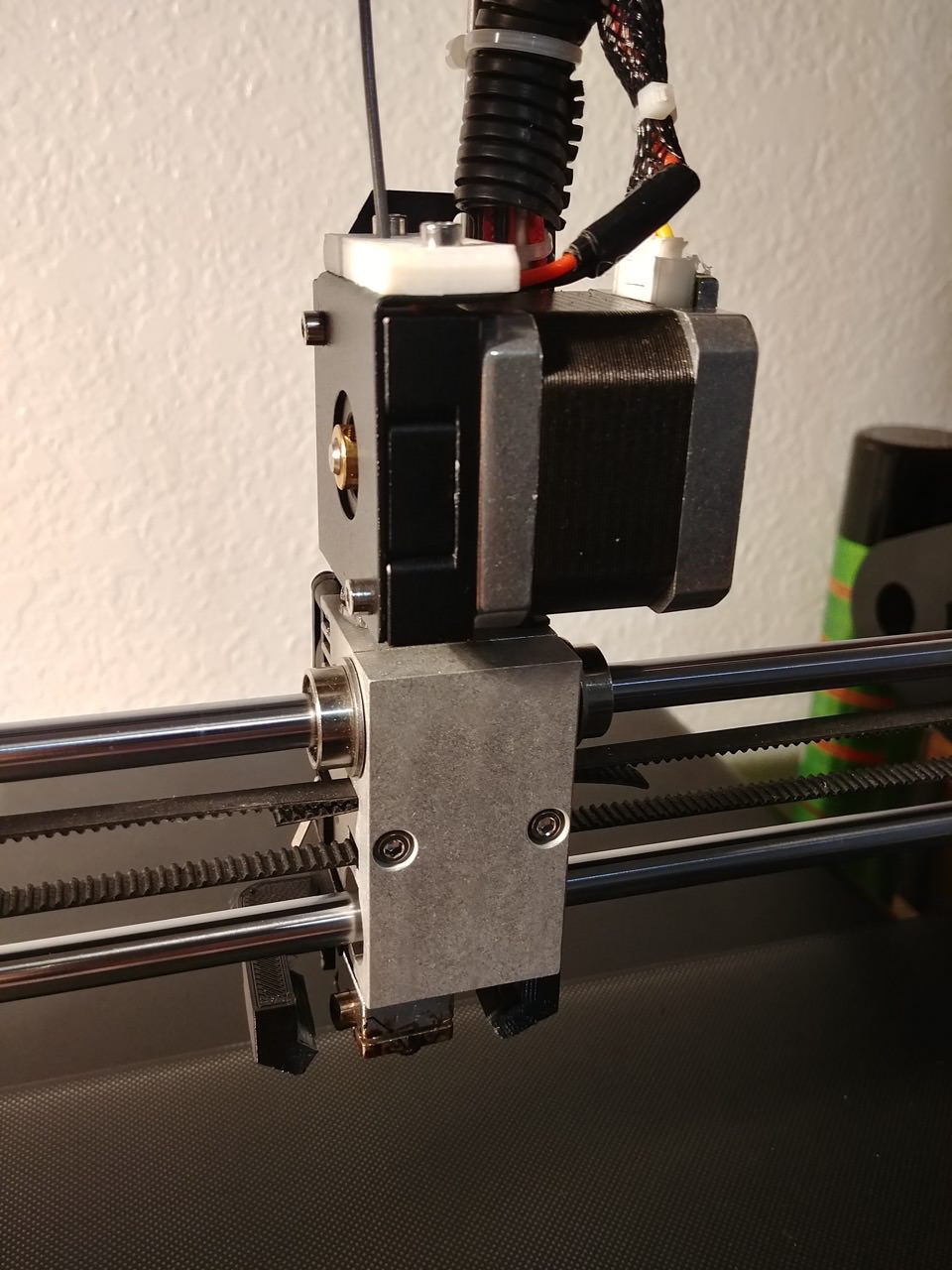

I used the original extruder mount and everything but I had to make a slight bend to the bottom of it (actually its the original top of it) to clear the extruder fan.

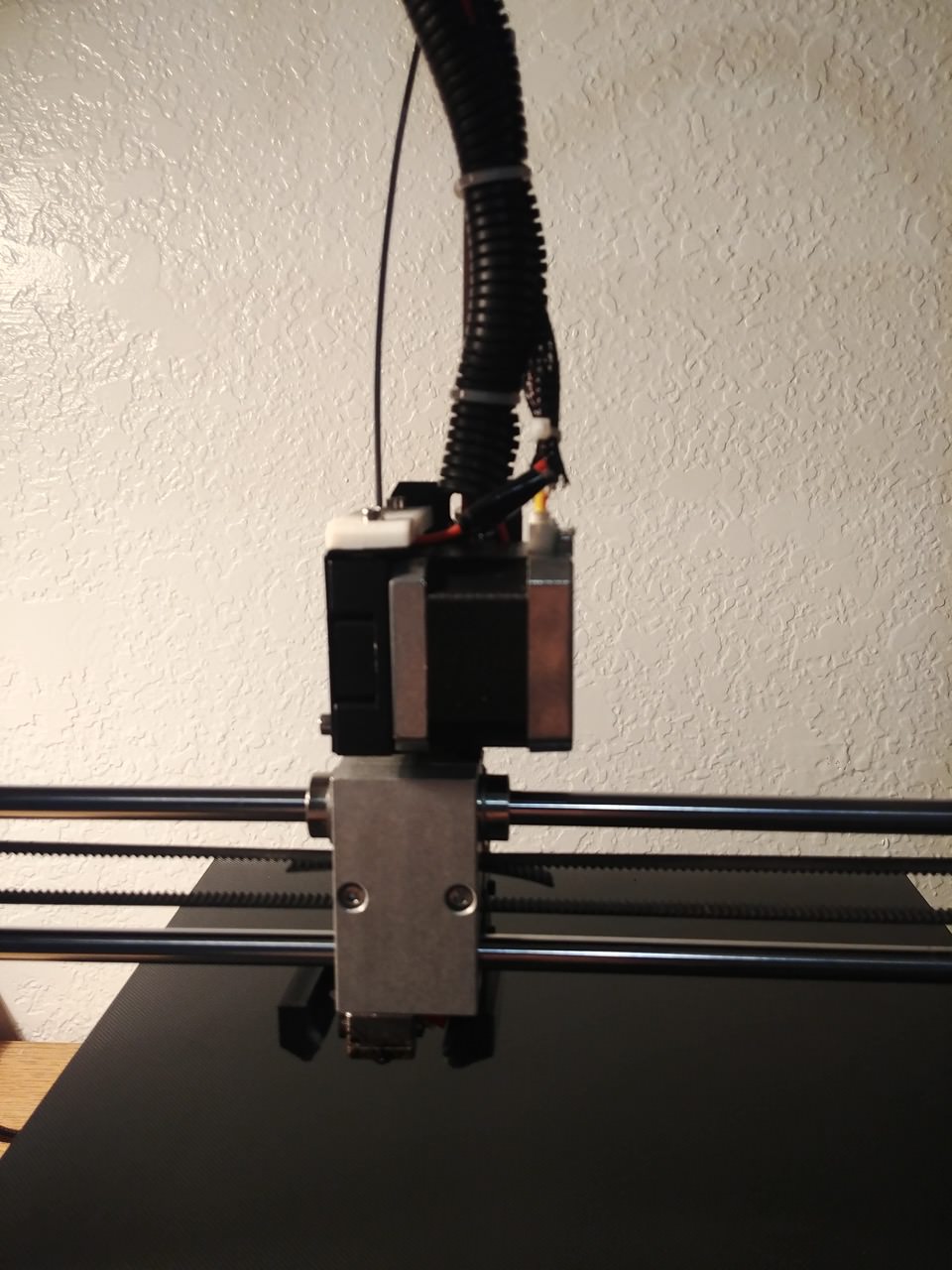

I then just drilled another couple holes beside the original mounting holes on extruder bracket and made a thin piece of flat aluminum to fasten the wires to to keep them solid as they were bending to much right on top there. But anything could be used instead, I had a pencil fastened there at the start and it worked well.

I did cut off the extruder fan guard as you can see but didnt have too. That as before I bent extruder fan bracket which works better. I did obviously have to take extruder apart to screw it on there.

And thats pretty much it. I spliced the wires where they connect to the side of the A5 and put them all into that protective casing.

Been printing 0.2 layer prints at 80mm speed and they turn out real great

But I go a different way and will soon install this monster in my JGAurora:

I have written an article on how to build it but did not yet post that, the whole thing is und 60$ + a lot of printing^^

between Extruder an hotend.

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!