Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

Get transparent? But how...HD Glass vs. Vertex PLA natural, lets try that!

From time to time I think everyone want to try transparent prints.

There a couple of special transparent filaments out there, every producer say they are the best but is that true?

I bought HD Glass from Form Futura, many say they are the best in transparent filaments.

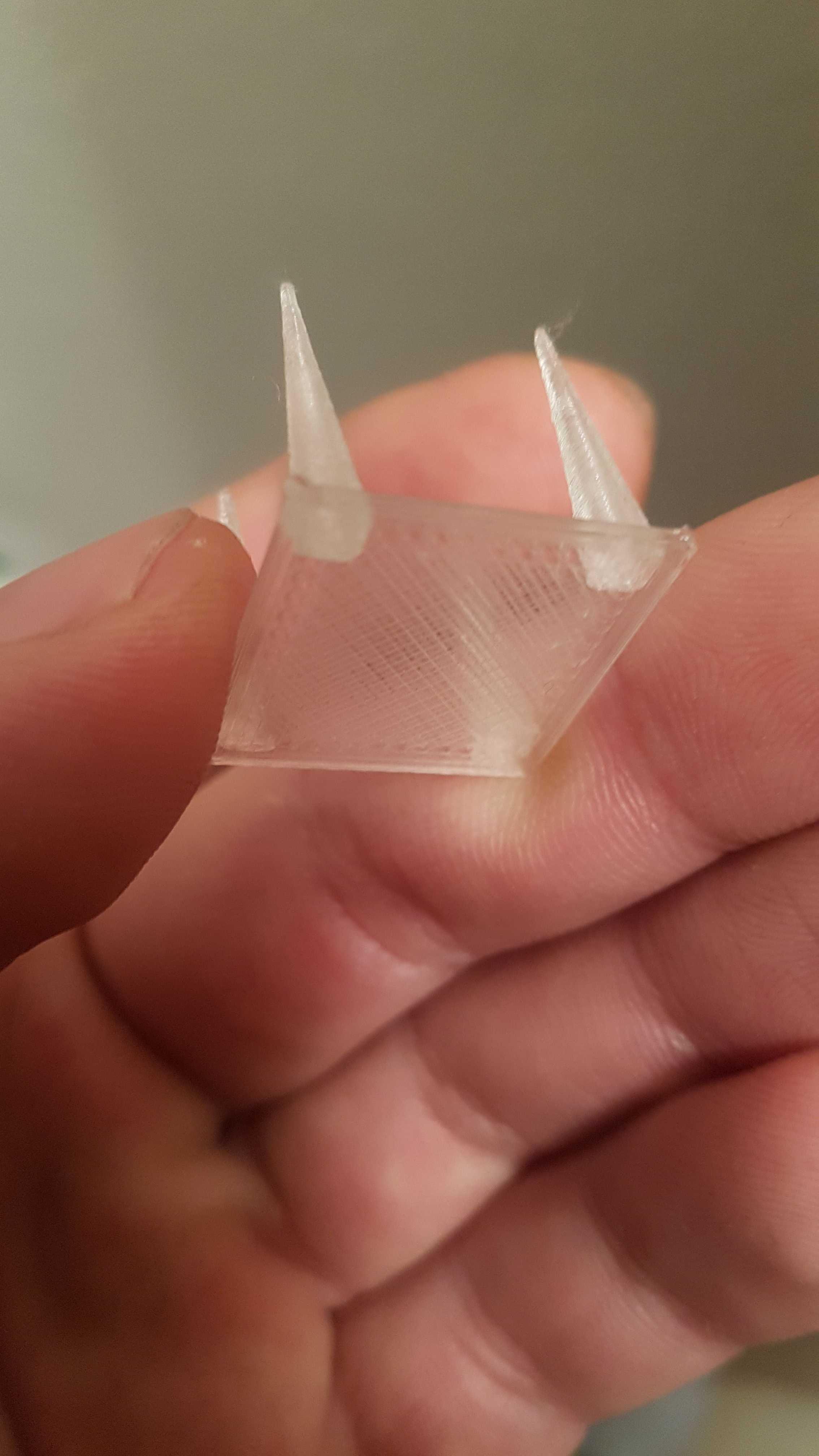

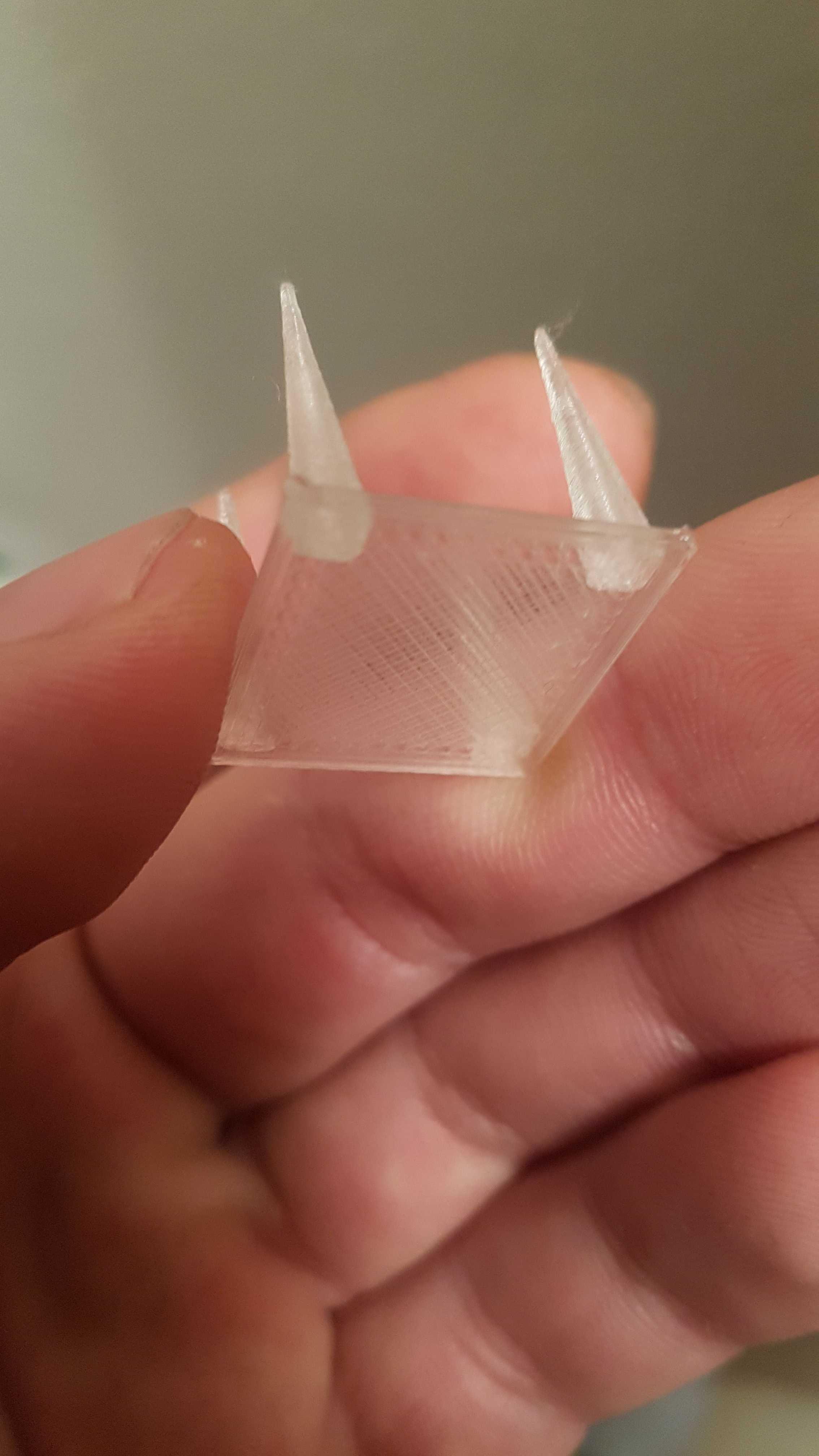

It is not the easyest filament to print. It doesnt string a lot for a PETG filament but it has many spots on it. Looking like little salt on the print. Its easy to clean but yeah, you have to clean it. A good print doesnt need to be cleaned.

It took me realy a lot of test prints to get the correct settings for it.

Next filament I have here was a mistake buy, it was PLA natural as I thought the colour would be beige. It is little milky.

The filament come from Vertex and is a 1,75mm natural filament.

So I thought, ok milky PLA I test it to find the settings and okaaayyy, its good for cheap prints what doesnt need a special colour.

But than after the first print.... First settings where nearly perfect, only little more retract and it was perfect! AND.... transperent!

Not only a little, it looks even better than HD Glass prints!!!

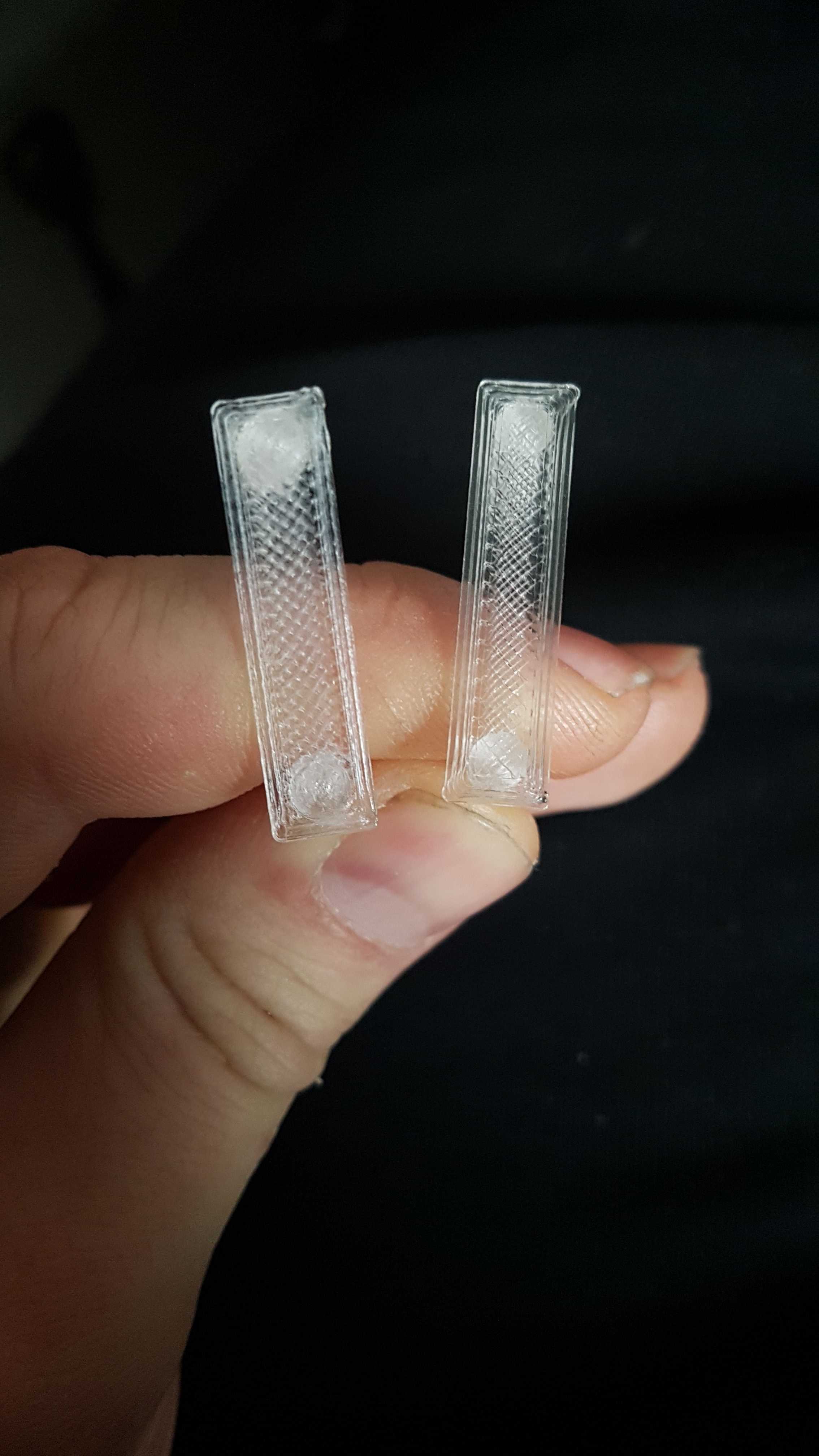

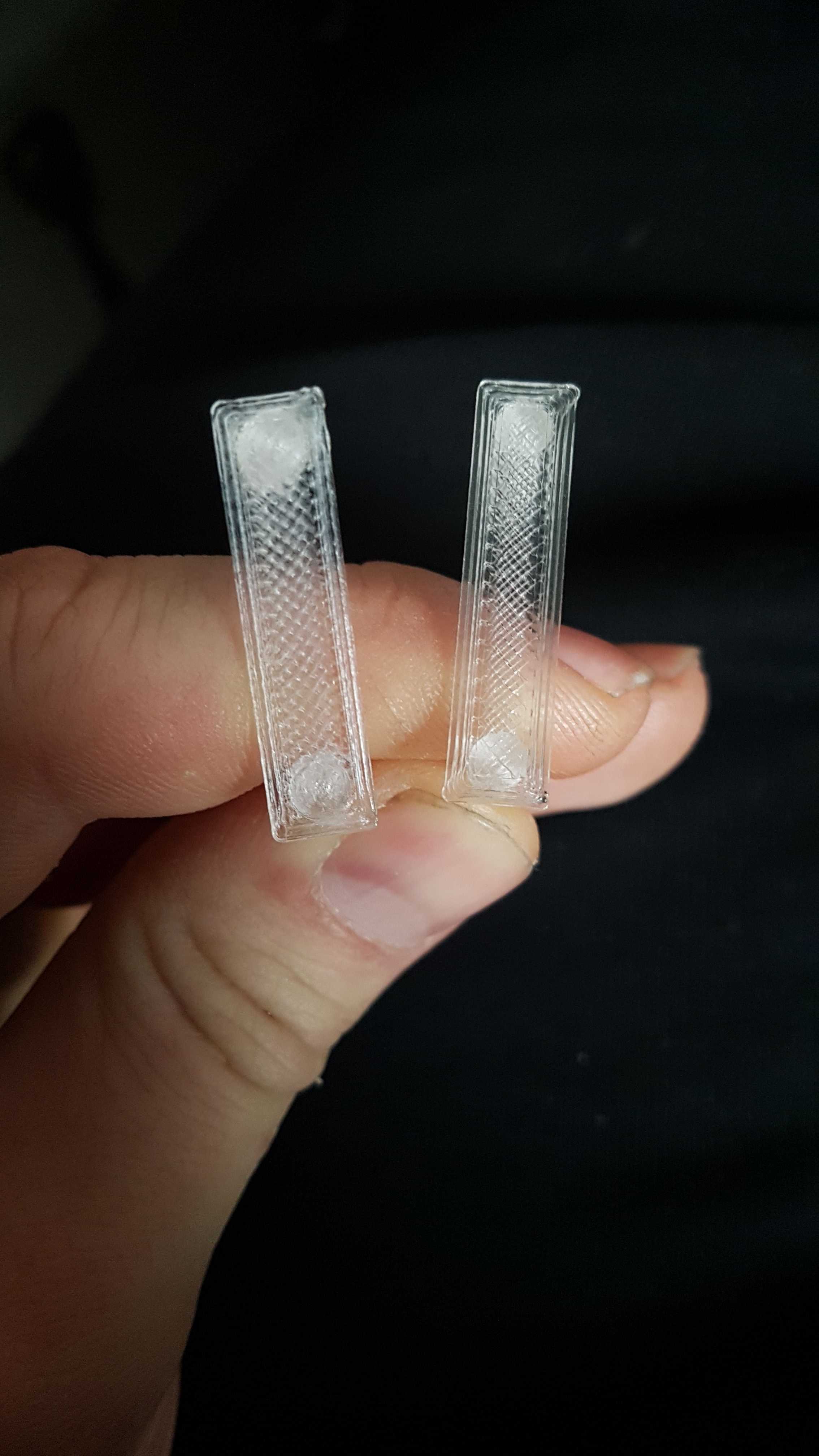

Here on the left its HD Glass, on the right its the Vertex natural filament!

What do you say? Its totaly awesome because it looks so great, has a price difference and the PLA is sooo easy to print!

If you need transparent prints and nothing to worry about, I would say, try it!

Ah and in generell, dont try thin layers with transparent filaments, that doesnt look good in the end, its better to stay with 0,2mm

There a couple of special transparent filaments out there, every producer say they are the best but is that true?

I bought HD Glass from Form Futura, many say they are the best in transparent filaments.

It is not the easyest filament to print. It doesnt string a lot for a PETG filament but it has many spots on it. Looking like little salt on the print. Its easy to clean but yeah, you have to clean it. A good print doesnt need to be cleaned.

It took me realy a lot of test prints to get the correct settings for it.

Next filament I have here was a mistake buy, it was PLA natural as I thought the colour would be beige. It is little milky.

The filament come from Vertex and is a 1,75mm natural filament.

So I thought, ok milky PLA I test it to find the settings and okaaayyy, its good for cheap prints what doesnt need a special colour.

But than after the first print.... First settings where nearly perfect, only little more retract and it was perfect! AND.... transperent!

Not only a little, it looks even better than HD Glass prints!!!

Here on the left its HD Glass, on the right its the Vertex natural filament!

What do you say? Its totaly awesome because it looks so great, has a price difference and the PLA is sooo easy to print!

If you need transparent prints and nothing to worry about, I would say, try it!

Ah and in generell, dont try thin layers with transparent filaments, that doesnt look good in the end, its better to stay with 0,2mm

Comments

The next filament I set up for my test prints was Colorfabb PLA transparent green.

Its should be the same like the natural one but it was soooo horrible to set up in my test prints. Its a totaly different setting on the printer even it is nealy the same PLA type.

I dont understand that, it seems that I always have problems with filaments out of the netherlands

Also the Colorfabb PA Neat is simply horror, it was new, in a light vacum packed spul and printed like it was not packed.

It does only ooze the whole time and is so hydrated that you cant print it, now its in the oven....

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!