Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

Strange First Layer Printing Problems

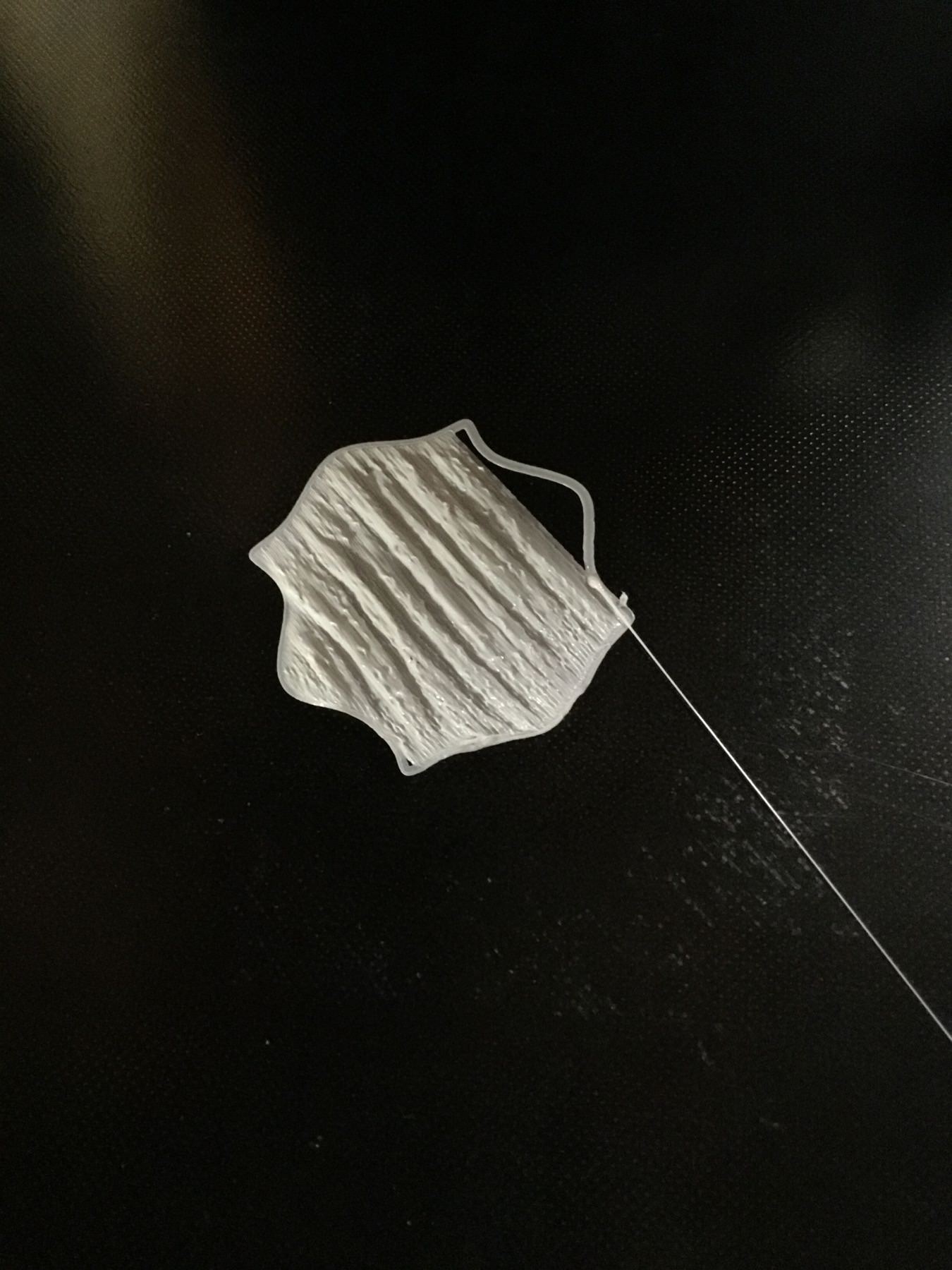

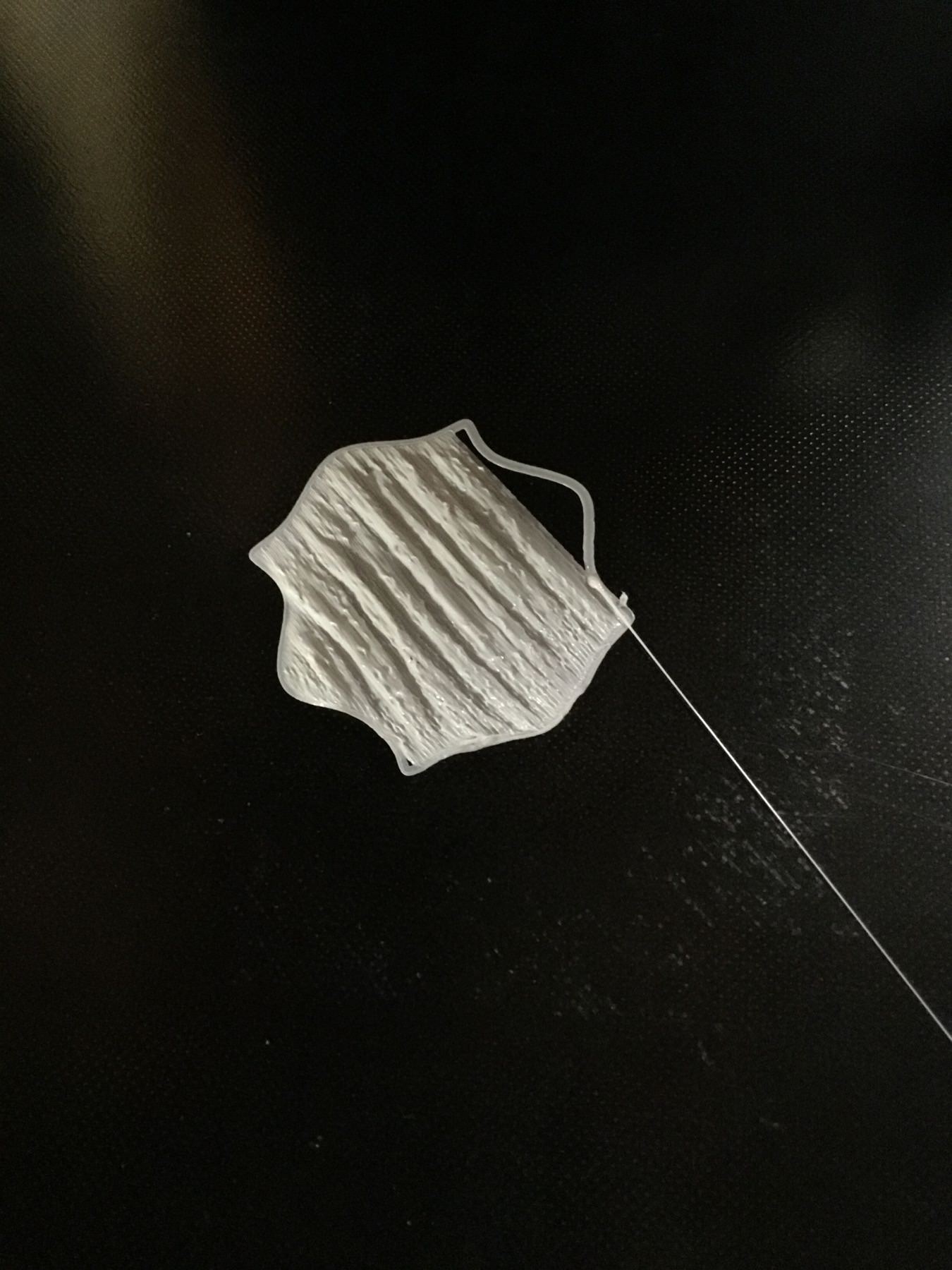

this is my initial layer (bottom of a vase). What could be wrong?

Post edited by Samuel Pinches on

Comments

.12 first layer height

12mm first layer speed

leveled the bed again to .075 with paper

bed at 67c

This photo is looking at the bottom of the vase after printing.

The first layers are bad but the rest is beautiful.

Is this underextrusion? The first few layers of the bottom are not “smashed” down on the bed as I would expect. Any more help is appreciated. Thanks

https://m.youtube.com/watch?v=MaEumQiUESo

Additionally I print a skirt everytime and use the babystep buttons to adjust the height.

Strangly I have to press Baby - arround 6 times to archive optimal heigt, so I used

G29 S4 Z-0.15

M500

To move the mesh 0.15 (6 babysteps) to the negative on the z axis.

I can now print a consistent 1st layer on my 50 C bed, and then turn the bed down to 30 C for power consumtion...

Meshes rock^^

They move the hotend by 0.025mm up or down for the current print only.

So I stay with the printer while its printing the skirt and adjust printing height, after a few tries you can easily see if the nozzle is to high and the plastic falls on the bed or if its to low and the plastic is squished so flat you can see right through it in the middle of the line.

I would still use the mesh because I find it difficult to level the middle of the bed, where i have to adjust all 4 screws the exact same amount to not influence the other 4 points. Mesh leveling is also far easier and faster in my opinion.

Problem is that the bed warps when it gets hot, you cant prevent that because it consists of more than one material, that probably acounts for your varying experiences when leveling at different temps.

The only way to compensate for the warping is Mesh bed Leveling. (or buying a new bed composed of just 1 material)

My first successful pints I also increased temp and flow, but that got me other problems like warping and elepfants feet and so on, you really need to mesh^^

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!