Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

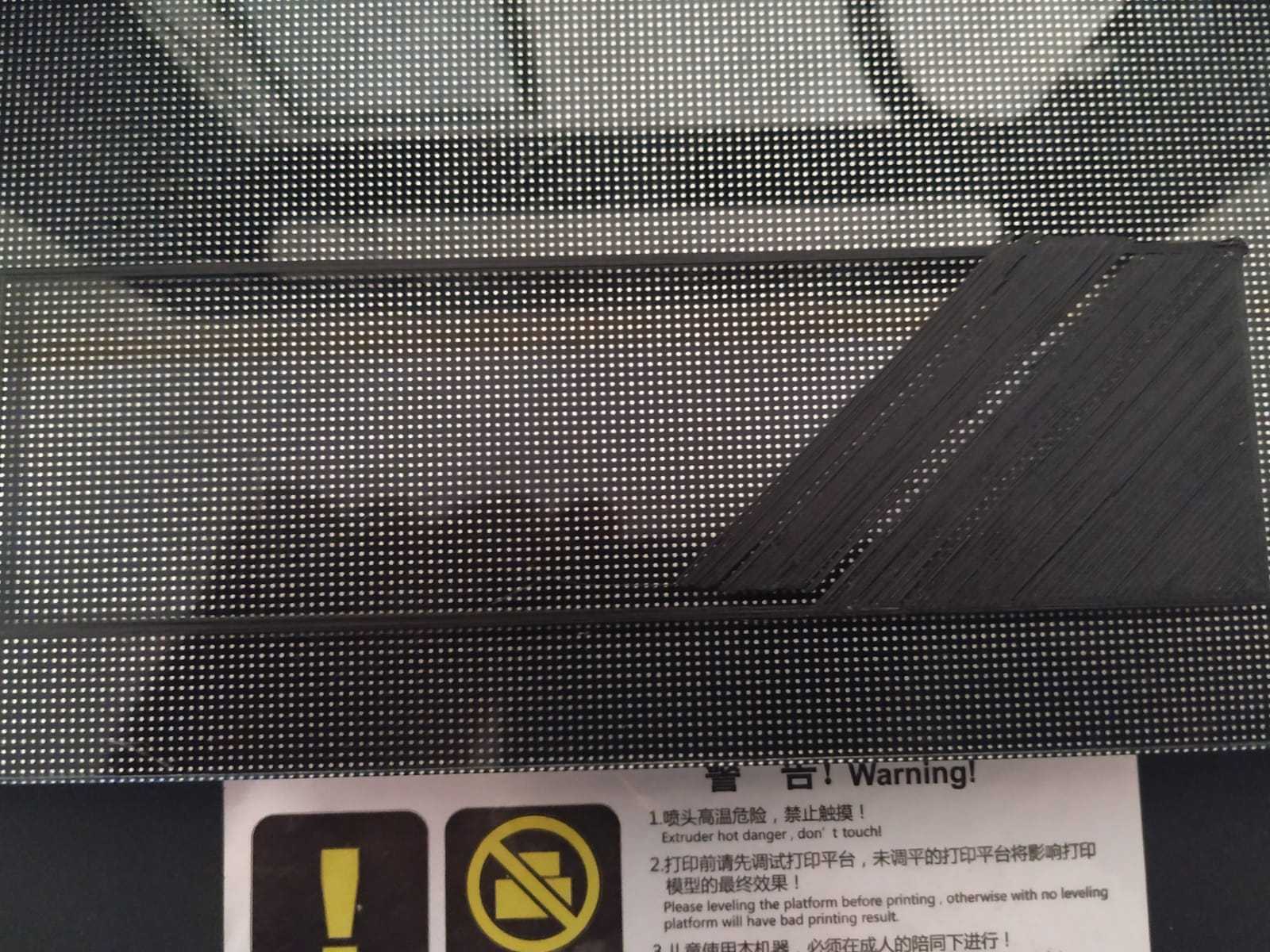

Print trail shifts whilst printing

Matt

Posts: 314🌟 Super Member 🌟

Matt

Posts: 314🌟 Super Member 🌟

First printing attempt after recovery & flashing... I'm obtaining what's in the picture. At each layer shifting, a "tuck/thud" noise was heard from the printer... Lubricated with lithium the screws. Trying another attempt. Printed at 50% speed.

Live update: whilst I was writing this, the printer stopped printing and cried the beep which is done at startup, and apparently the printer restarted... Perhaps the firmware flashing was anyway badly done...

Now I'm at third attempt, 100% speed, and apparently is faring good.

Post edited by Matt on

Comments

herer it is>

https://jgaurorawiki.com/a5/stepper-drivers

If you have stock A4988 drivers, you find table in article for each axis Especially Y axis is critiacal, as it needs to move big mass of material-hotbed

You need flat tip screwdriver-best is from kit for repairing watch, as it need very small tip and digital multimeter to correctly set Vref voltage.

No need to worry for setting exactly specific value. +/- 50 milivolts does not play critical role. Easiest way is to make small movement of trimmer on driver and measure voltage. Then again rotate and remeasure..

do not worry..It is job for 15 minutes + disassembly and assembly of printer

https://www.amazon.com/ARCELI-Compatible-Stepper-StepStick-Controller/dp/B07MY2SWQ5

If yes, table with voltages is same.It is just rebrand.

To the new printer..My plan is to build printer with direct drive, based on linear rails, not smooth rods and not cartesian style. I already made X axis. This will be long run to finish anyway as everything is closed here in Slovakia

Also if they are set too high, drivers will overheat and shutdown for a while until they cools down below threshold

You do not need AC power for this step, so less dangerous

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!