Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

Newbe here, input please

Hi,

i am New to 3d Printing,

and got me an A5, ...

I did try to find my settings; with Lots of reading and some Internet Pages mixed together i found some Cura settings that seem to work the Out of the stick version did not -

the alu extrusion rods for the enclosure are not even ordered yet

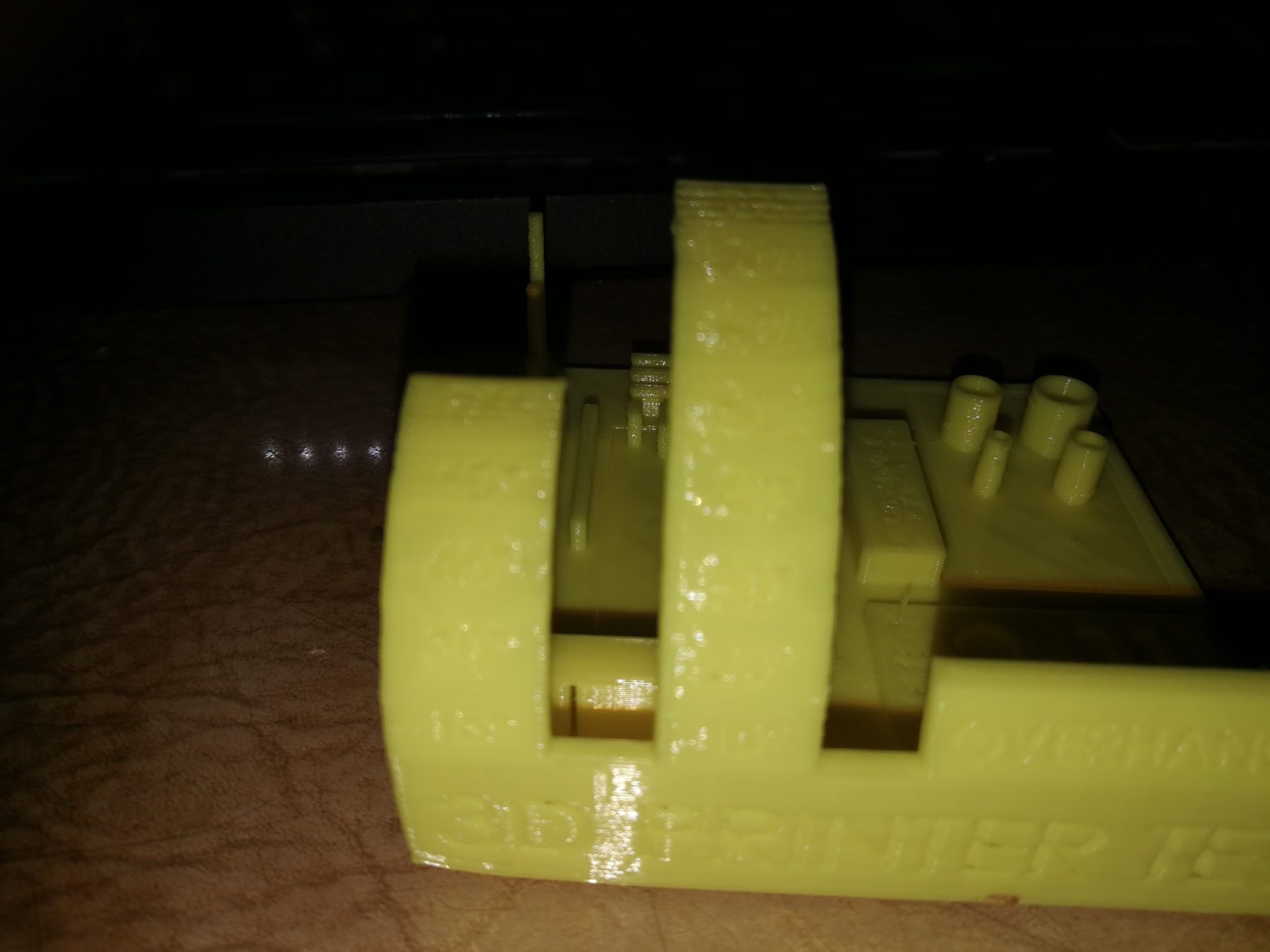

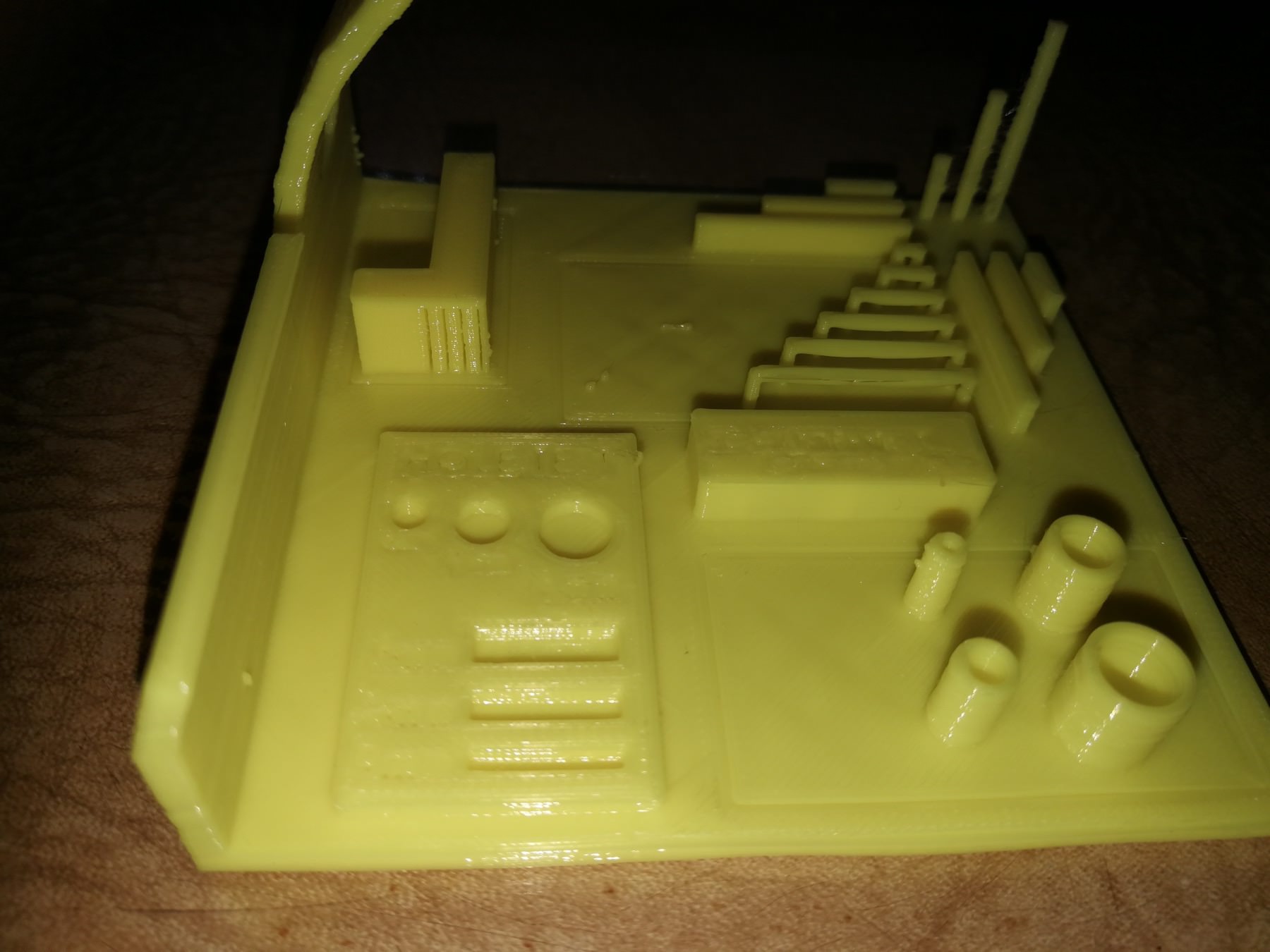

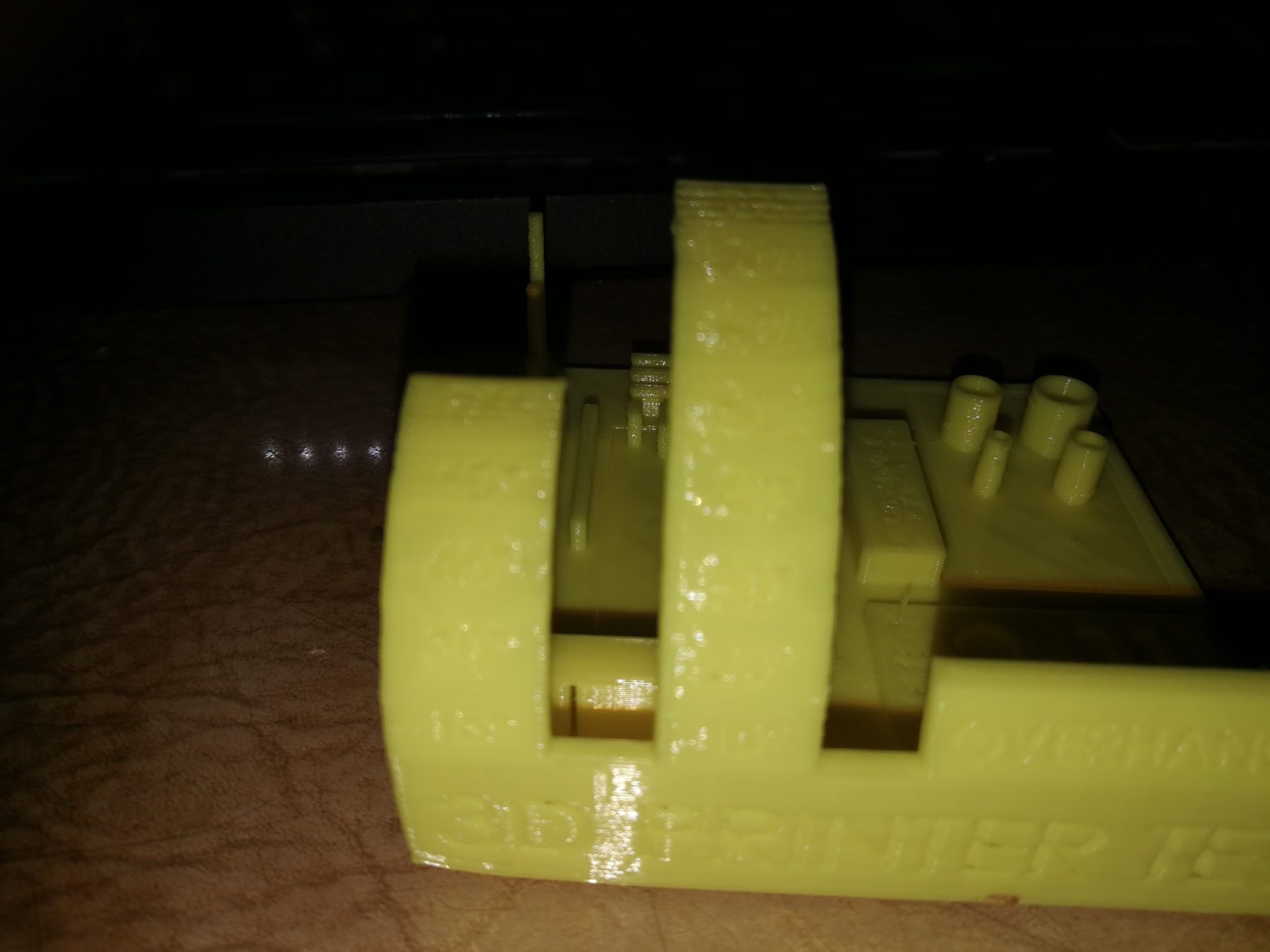

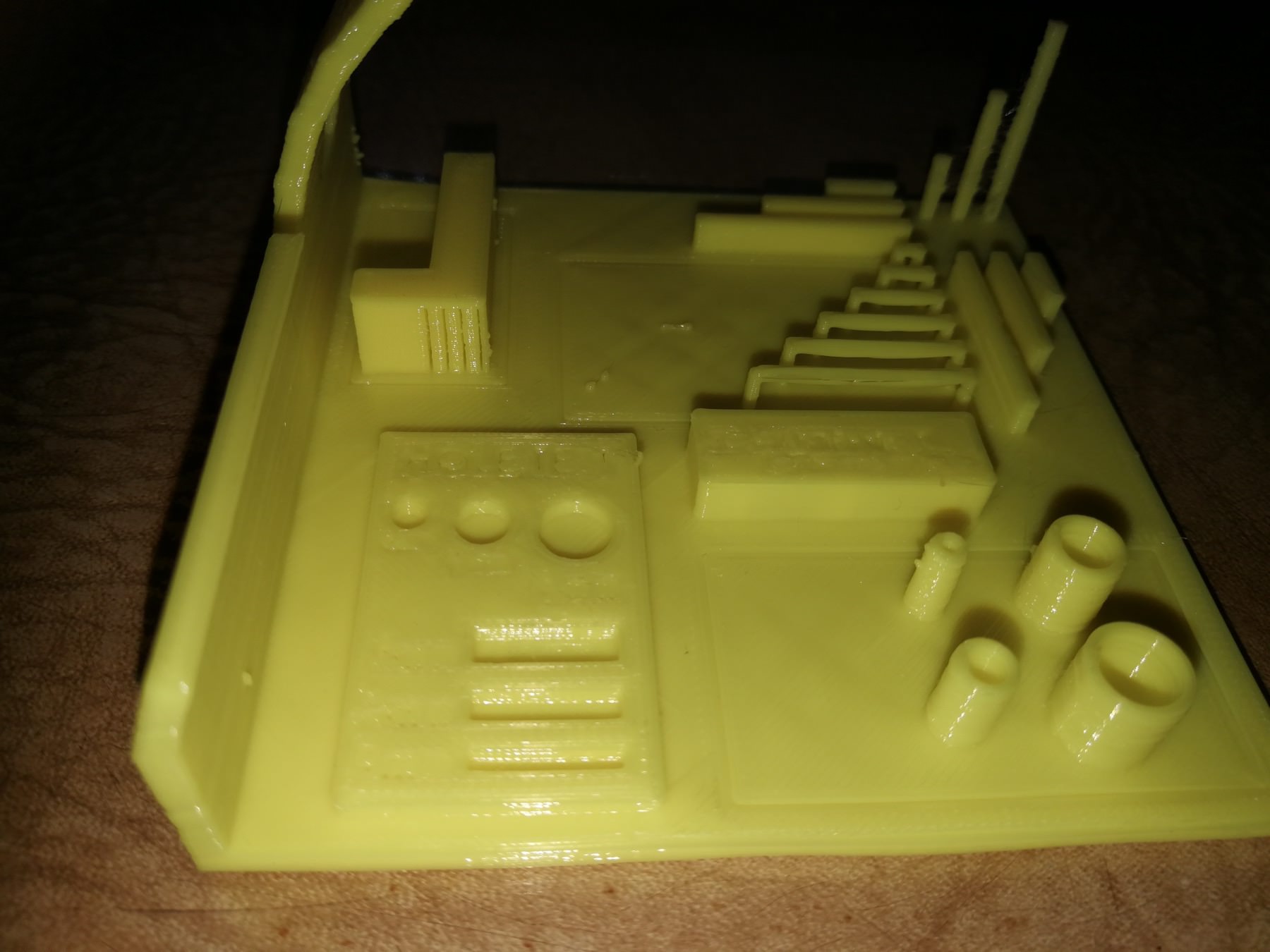

The pictures show the test Thingy i found here in an other threat ( i think the 7. thing i ever printed and the third that worked ,

,

And now i am on the hunt for the perfect settings

what i Got, and you also see some of the problems - I would love some input, of people that know what they are doing as i am kind of fumbling in the dark here i am still on my Trial PLA roll

Sorry for my crappy English, i am not nativ ,)

Best regards

Eye

Machine settings

xyz 305, 305, 320

plate rectangular

Heated bead

G code flavor Marlin

Head settings xy min 20, 10

Head settings xy max 10, 10

Gantry Hight 999999 mm

the changed cura settings i mixed together

Global

Quality

Layer Height 0.3

initial Layer Height 0,27

Material

Default build plate temperature 60

Build plate temp 67

Build plate temperature Initial Layer 67

Travel

Combing mode Noskin

Support

Generate Support False

Build plate adhesion type skirt

Extruder 1

Quality

Layer height 0,2

infill

Infill Density 10%

Material

Default Printing Temperature 220

Printing Temperature Calculated

Printing Temperature Initial layier Calculated

Initial Printing temperature 205

Retraction Distance 10

retraction speed 60

Speed

Print speed 40

Infill speed 60

initial layer speed 15.0

Cooling

Fan speed 50.0

Regular fan speed at layer Calculated

Build plate adhesion

Skirt Line count 2

Skirt distance 10

Brim width 10

Experimental

Enable coasting True

i

i

i am New to 3d Printing,

and got me an A5, ...

I did try to find my settings; with Lots of reading and some Internet Pages mixed together i found some Cura settings that seem to work the Out of the stick version did not -

the alu extrusion rods for the enclosure are not even ordered yet

The pictures show the test Thingy i found here in an other threat ( i think the 7. thing i ever printed and the third that worked

And now i am on the hunt for the perfect settings

what i Got, and you also see some of the problems - I would love some input, of people that know what they are doing as i am kind of fumbling in the dark here i am still on my Trial PLA roll

Sorry for my crappy English, i am not nativ ,)

Best regards

Eye

Machine settings

xyz 305, 305, 320

plate rectangular

Heated bead

G code flavor Marlin

Head settings xy min 20, 10

Head settings xy max 10, 10

Gantry Hight 999999 mm

the changed cura settings i mixed together

Global

Quality

Layer Height 0.3

initial Layer Height 0,27

Material

Default build plate temperature 60

Build plate temp 67

Build plate temperature Initial Layer 67

Travel

Combing mode Noskin

Support

Generate Support False

Build plate adhesion type skirt

Extruder 1

Quality

Layer height 0,2

infill

Infill Density 10%

Material

Default Printing Temperature 220

Printing Temperature Calculated

Printing Temperature Initial layier Calculated

Initial Printing temperature 205

Retraction Distance 10

retraction speed 60

Speed

Print speed 40

Infill speed 60

initial layer speed 15.0

Cooling

Fan speed 50.0

Regular fan speed at layer Calculated

Build plate adhesion

Skirt Line count 2

Skirt distance 10

Brim width 10

Experimental

Enable coasting True

i

i

Comments

Generally I would print with 0.2mm layers or less. 0.15 is a good height to aim for

i did some more experiments; and use of a Lego brick for "tweaking"

The difference From 0.1 layer to 0.3 layer is significant, from 15- 90 minutes for one Lego brick

I bought some kilo spools and i found now that the different types of PLA do seem to Try to make it extra difficult,

Finding Some Heat that the Stuff STICKS on the Board is Less then fun !

the white one i have ATM, works once, THEN does not Stick at all with the same settings,...

i have designed a little part for the alu extrusion box i am building For the Ag, and the FIRST come out okisch moist times; one side greate Corners the other; less so

And Then; when i try tp Print a 2ed With the same settings.,.. Desaster...

That all had me restarting with the heat settings for the new material like 20 times

can it be that it i to HOT after beeing in use fro a whiel; , that the sensor heat and the Bed heat are not the same?

i designed a ral for a door , and becorse of shaking it gets bad at 10 cm, so i Cut it to 5 cm Pices,..

if i print one, all is fine, if i print several at once, it gets NOT good,

if i print a second with The exact same settings... and did not Waite 20 minutes or so (for cool down ?) it does not work, (one Platic blob)

yet if i print one after the other ; with a cupple of minutes between; i t works fine... So at the monet i am at 5 cm / hour

seems like A the temperature is not uniform ofer the whole plate,

and B, the plate is not having the same temp like the plate had before only due to the sensor claimng it to be...

does that sound paranoid?

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!