Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

Warping Problems

Hello,

now that I corrected mit Z Axis height problems, the next step ist warping:

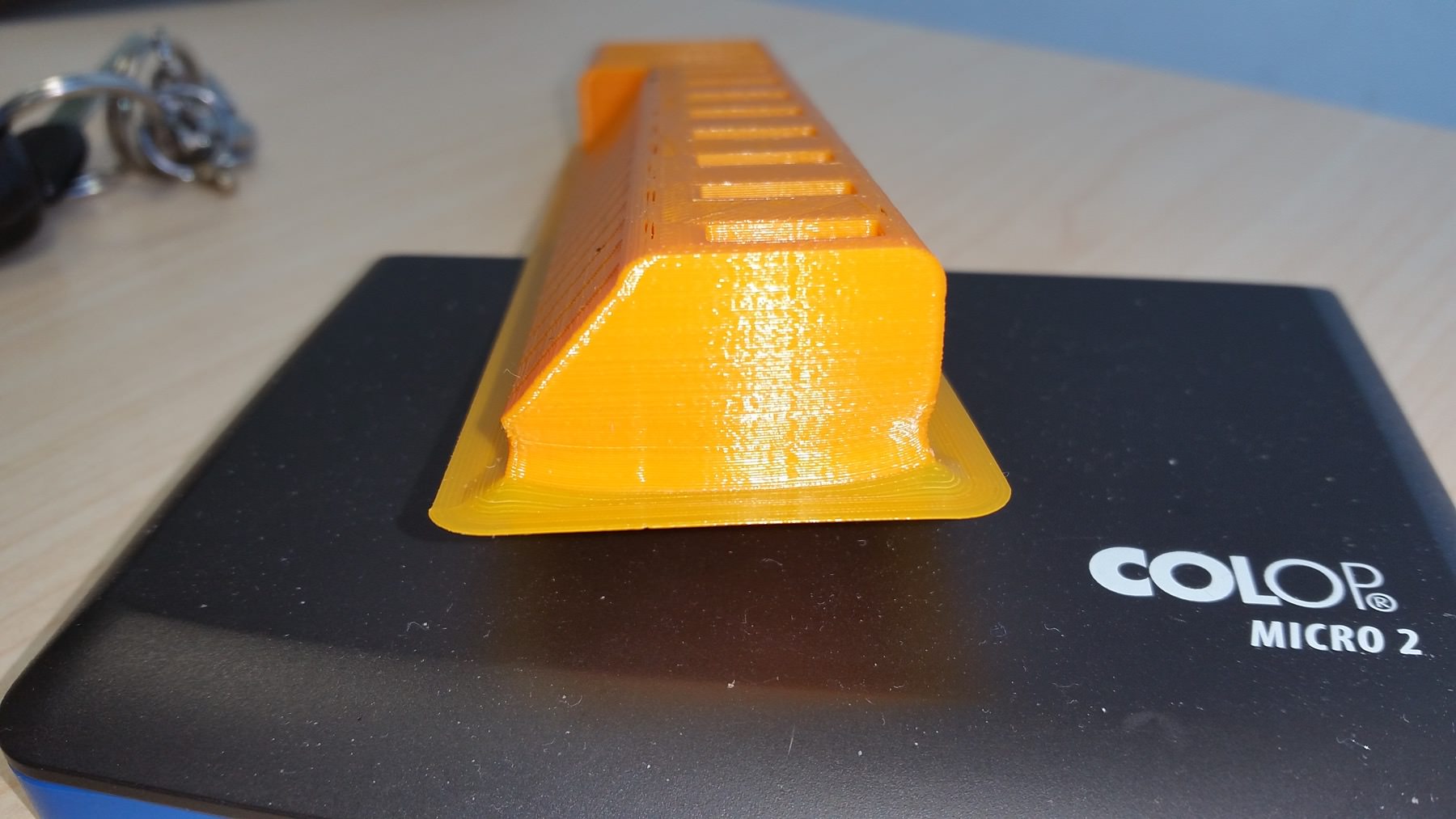

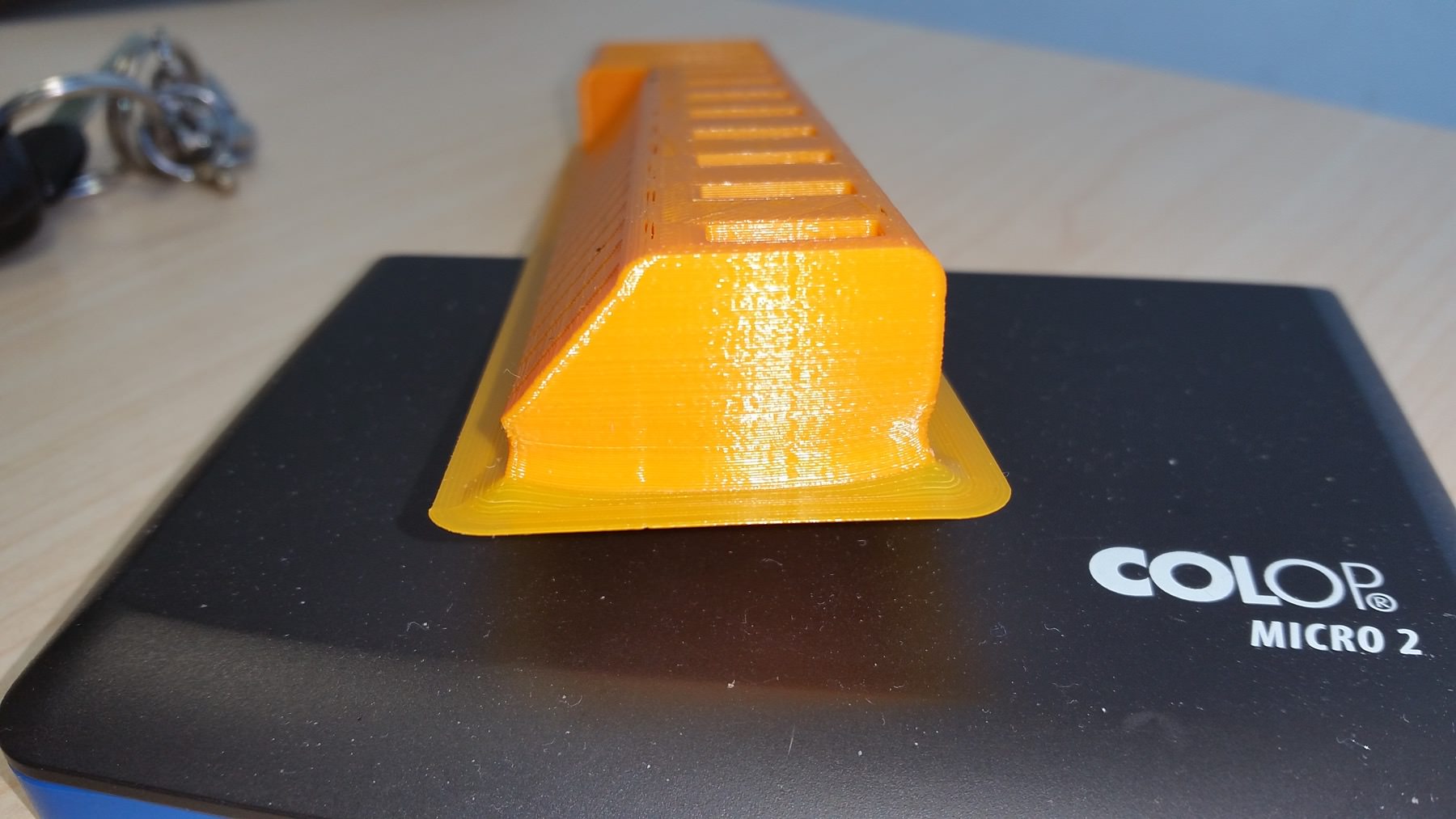

This is the USB Stick Holder I printed yesterday.

My Settings are as following:

215 C initial layer to get it to stick, 195 C all other layers

65 C Bed (it has really strong adhesion, so there must be considerable force at play to warp it and pull the brim of the bed)

100% Fan after the first layer

95% Flow (100% first layer) Because the all in one printer test fails at tolerance tests with 100% flow

all layers 0.2mm

10% infill

Speeds 10/12/30/60 (brim, i layer, walls, infill)

What I already tried:

Tuning the fan down gets me other problems.

Increasing Flow gets me problems with small gaps.

5 C more or less bed temp does not change much.

Dialing down initial layer temp makes the brim less sticky

A thinner first layer is weaker and therefore the warping increases

I clean the bed with alcohol before every print, I do not want to use any additional glue on the bed, its only pla and i am sure it has to work without pva sticks or something.

Any help is apreciated...

kind regards

Martin

now that I corrected mit Z Axis height problems, the next step ist warping:

This is the USB Stick Holder I printed yesterday.

My Settings are as following:

215 C initial layer to get it to stick, 195 C all other layers

65 C Bed (it has really strong adhesion, so there must be considerable force at play to warp it and pull the brim of the bed)

100% Fan after the first layer

95% Flow (100% first layer) Because the all in one printer test fails at tolerance tests with 100% flow

all layers 0.2mm

10% infill

Speeds 10/12/30/60 (brim, i layer, walls, infill)

What I already tried:

Tuning the fan down gets me other problems.

Increasing Flow gets me problems with small gaps.

5 C more or less bed temp does not change much.

Dialing down initial layer temp makes the brim less sticky

A thinner first layer is weaker and therefore the warping increases

I clean the bed with alcohol before every print, I do not want to use any additional glue on the bed, its only pla and i am sure it has to work without pva sticks or something.

Any help is apreciated...

kind regards

Martin

Thanked by 1Samuel Pinches

Comments

Regular Fan Speed at Height: 1.2mm

I will definitely try that!

The squishing the first layer technique also allowed me to insert a ChangeAtZ Script that turns the heated bed down to 30 Degrees at 3mm. This saves lots of power and I have no chances of removing the print while the bed is at more than 25 C anyways^^

Then I used the information in this Video:

to print a 28 mm miniature, my very first try is already all the print quality I am ever going to need^^

Atm I am working on tolerances again, I am at 0.35mm and thats bad i want to tune it to 0.2mm max.

Also I found the "Number of slower layers" option which is great, since I start cooling late I need to print slowly in the beginning.

Note that changing bed temp from 25 to 60 changes its level for some 0.3mm.

The solution for this is to used a cast aluminium bed. Unfortunately no cheap printer uses this.

I use the same about the fan, just was curious how Prokktor does.

(I am using the blowhard 3000 design by Da Hai)

Thats the beauty of "Number of slower layers", it slowly increases print speed at the same rate the fan increases its speed.

The alternative is "Minimum Layer Time", but that is a constant over all layers.

Still with a large print you need less slow layers, i found no way to make that automatic.

Maybe a stack of "ChangeAtZ" scripts that change minimum layer time, no I fear Cura does not allow for that,

Oh yes you are right, my bed only raises about 0.15 from 30 to 60 but that might be a problem.

Small things I can print on the border because most of the bed warp is in the middle.

I will try multiple ChangeAtZ and alter the bed temp in many steps.

ATM I print at 85% extrusion and it still fails the .2mm test, that might indeed be the raising bed...

Edit: No its at least not only that because that would only account for errors between 3mm and 4mm print height.

I have more than enough bed adhesion at my current 60 C, so I will try a 50/55 C bed that drops by 5C every 1mm, that should take care of the problem.

Thanks for the tips!

Ah one more thing:

I read an article about first layer height, it states the first layer height should be less then the normal layer height because then the same amount of plastic is squished in less space to get more bed adhesion.

That indicates that "first layer height" does not influence flow rate which i find bewildering. Doubling Layer height and doubling print speed will of course double the flow rate... so how am I supposed to know which other options are not changing the flow rate automatically like I believe they would?

Measuring laser temp says the top of the glass has some 10deg less than thermistor says. Worth to find and tune it in Marlin, or remember making print settings. So if you plan 50, it means 40 :-).

Can you tell what and how you have fixed with Z mentioned in this post first line? I have impression that or my bed, or my x-axis or something with z has problem effecting 0.15mm in bed centre, hard to investigate it 100%. But definitely if I press right Z leading screw the nozzle comes down near 0.15, if pull it up nozzle same comes up. Like clearance on leading screw or motor axis. On left screw I can't see the effect so clear.

They are at 10mm height, while the bed temp changed between 3 and 4mm.

So I still believe I am on the right track :-)

My Bed is actually 1 to 2 C hotter than the printer says, I measured with thermistor and infrared with similar outcomes, my nozzle is about 1% to cold. Thats ok for me so I did not recalibrate.

Sorry but I am unable to understand what you mean with the "fixed with Z" part.

My bed middle goes down about .2mm when heating from room temp to 65C, I measured that by simply reading the output of G29 (S0).

Did you mean that?

This is what I've meant:

"Hello,

now that I corrected mit Z Axis height problems...."

So I used:

G29 S4 Z-0.2

M500

To fix that^^

Currently I leave it 0.1mm to high and correct by babystepping at every print. So I dont have to remesh when using a different bed temp.

I am now at 80% flow and it passes the 0.2mm test, printing with 77% flow now^^

Why is that thing overextruding so much:

Idea: I saw youtube videos claiming it would be underextruding by 20% and I also saw videos claiming it would be overextruding bei 6% (thats a good one and probably unknown here so I link it)

So the community firmware fixes the 20% underextruding, and since I had a 6% overextruding model, its now 26% overextruding?^^

I the tried .45 nozzle size and 100% flow: didnt even pass the 0.4mm test.

Then I found this extruder calibration test:

https://www.thingiverse.com/thing:2372705

which prints in little over 10 minutes.

I went down to 70% flow until i got the s'es pressed together.

My problem at the moment is that I see signs of under extrusion when I go to far below 80% flow especially in the top layer, but if i want to print small gaps I need to go below 70% so they dont get filled with squished filament.

Are there any other option to tackle one of those problems without worsening the other?

I never thought about my bearings so far but they at least seem fine^^

I thought about the die swell some more:

Cura calculates filament steps by:

Extrusion Width * Extrusion Height * Speed / Filament Width

and extrusion width is calculated from nozzle size and wall thickness.

So when I changed nozzle size to 0.45 but leaving wall thickness at 0.8 he than tried 1 line of 0.8mm thickness which is probably not causign accuracy to improve^^

I am now trying 0.45 nozzle size and 0.9 mm walls^^

I read many articles about that a few days ago, and they all state that max height is .7 or .8 times nozzle width.

so with a .4 nozzle you can print .4*.3 mm², thats 0.12mm2.

Would you happen to have a 1mm nozzle you could print 1.0*0.75 that is 0.75mm², which is more then 6 times as much filament^^

(if the heating element is strong enough, I have no idea, but I will test 0.8 and 0.6mm nozzles once they arrive)

Widening the nozzle size in cura did not help in a meaningful way, I went up to 0.6mm at 0.5mm it might have been a very tiny improvement over 0.4, but that might have been random.

So I went back to 0.4mm,

My tolerance problem stays. I settled for 80% flow, since there are next to no signs of under extrusion then. It passes only the 0.2mm test...

Yesterday I printed three more detailed 28mm dnd figures and I actually learned something: All the temp towers are completely useless, I could spot no difference from 190 to 230 C there because they are to easy to print. With my figurine I saw that at 210 C the nozzle heated up small details during print and the looked frayed, also the high temp caused minor stringing. When printing at 190 C those problems where gone. Steep overhangs that normaly would need support actually look better with higher temps, but they still look bad so I would rather print the support then causing other problems with higher temps.

The initial layer is printed at 210C because at 205C it does not stick^^

Bed Temp: I found that more than 50% of the warping happens from 50C to 60C, so I now start out at 50C and lower the temp by 2C every 0.5mm, that does not cause any problems. My Final temp is 34C at 4mm.

And here is the little guy:

The halbert head was ONLY printable with "minimum layer time" in combination with "lift head" so that after each layer the print head moves away from the halbert. Just slowing speed is of no use because if the nozzle remains in contact it heats up the previous layers and everything forms a long blob.

I will perform some more tests today and then publish my profile.

PS: I a still looking for a way to solve my tolerance vs underextrusion problem.

PPS: The Knight actually looks much better then my first figure, but the harsh office light and zoom make every flaw visible. From 40cm away I cant even tell its printed with my eyes^^

But then I still dont know why the warping is such a big problem.

Ok the underside of my prints is warped by 0.2mm max from one end to the other, and I have to make a new mesh leveling everytime I need to print at a different bed temperature.

The Mesh bed leveling takes 2 to 3 minutes, so I dont think I will change anything about the bed, apart from my insulation to conserve energy.

What I will do is install TCM2XXX stepper drivers and probably a full metal hotend with direct drive.

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!