Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

guidance regarding cooling fan speed while building the raft layers

AON

Posts: 19Member

AON

Posts: 19Member

I am a novice with about a week under my belt.

I have discovered that my objects with pointy shapes laid on their side (on the bed) warp without a raft.

I originally tried a brim and the brim warped at the poits which caused the object to scoop upwards at these points upon building.

When I use a raft the PLA material build is stable.

However, the raft has four layers.

I had the fan OFF for the complete raft.

The raft third layer warped upon deposit.

I turned the fan ON half speed (50%) for the middle and 100% for the top.

The middle ended up being 90% through layer two of four.

Layer three warped upon deposit.

My raft build speed is 15mm/sec.

I find my feed gear does not chatter at this speed... it had started at layer two before.

Extruder temp is 215°C; originally it was 210°C

Bed temp is 55°C

Print speed is 25mm/sec as the feed gear does nt chatter at this speed; originally it was 30mm/sec.

feed rate is 95%; originally it was 100%.

I seem to have discovered the feed/speed/temp blend to eliminate the chatter.

I just cannot seem to get the third of four layers to deposit without warping (lifting/curling).

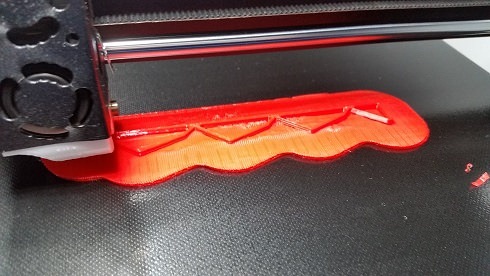

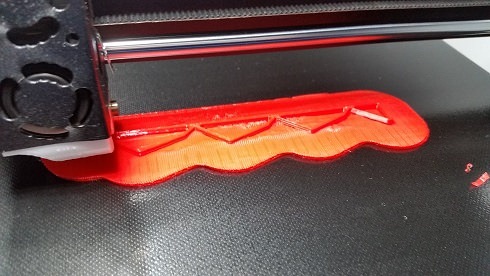

You can see in the pics below that the final layer tends to iron it out but it is not flat and it affects the raft removal.

Any suggestions?

(BTW the object is a dominoes rack for playing train. It is 10 inches or 254mm long when done.)

Thank you in advance for any help offered!

Alan

I have discovered that my objects with pointy shapes laid on their side (on the bed) warp without a raft.

I originally tried a brim and the brim warped at the poits which caused the object to scoop upwards at these points upon building.

When I use a raft the PLA material build is stable.

However, the raft has four layers.

I had the fan OFF for the complete raft.

The raft third layer warped upon deposit.

I turned the fan ON half speed (50%) for the middle and 100% for the top.

The middle ended up being 90% through layer two of four.

Layer three warped upon deposit.

My raft build speed is 15mm/sec.

I find my feed gear does not chatter at this speed... it had started at layer two before.

Extruder temp is 215°C; originally it was 210°C

Bed temp is 55°C

Print speed is 25mm/sec as the feed gear does nt chatter at this speed; originally it was 30mm/sec.

feed rate is 95%; originally it was 100%.

I seem to have discovered the feed/speed/temp blend to eliminate the chatter.

I just cannot seem to get the third of four layers to deposit without warping (lifting/curling).

You can see in the pics below that the final layer tends to iron it out but it is not flat and it affects the raft removal.

Any suggestions?

(BTW the object is a dominoes rack for playing train. It is 10 inches or 254mm long when done.)

Thank you in advance for any help offered!

Alan

Post edited by AON on

Comments

Once again layers one and two (front to back and diagonal ) went down nicely.

Layer three (side to side) with fan at half speed (127 RPM or 50%) curled.

I tapped it down with a short piece of filament as it was being laid.

Damage was minimal. Much better than the pic above in my first post.

Final layer four (front to back) with fan on at half speed is going down nice.

I am beginning to believe the direction of travel with fan cooling affects the way the filament reacts.

Side to side seems bad. Front to back seems okay.

Has anyone else experienced this phenomenon?

Alan

you are basically going through the same process as everyone else:

To achieve good 1st layer adhesion you need to follow some advice, else once your part cooling fans starts everything will warp:

- level your bed perfectly, best use automatic or mesh bed leveling

- your 1st layer needs to be squished flat by the nozzle

- your 1st layer temp needs to be higher then your normal printing temp, 210 to 220 depending on your filament is ok

- the bed at 50 or 55 C is ok

- start your part cooling fan slower and later

After doing all that you can print most parts without rafts or brims.

I wrote it all down here:

https://jgmakerforum.com/discussion/421/cura-profile-for-the-a5-and-explanations-for-the-individual-settings#latest

Thanks.

But still you did not heed all the advice contained in it.

- you are using the original JGAurora Fan Duct instead of the BlowHard 3000, that cools only from one side, leading to the behavior you describe

- it is risky to have 50% fan speed at layer 3 already, it is doable but makes it harder for you, if your print does not have steep overhangs below 2mm, set the regular fan speed height to 3.5mm

Does anyone know what the performance (air flow/pressure) rating of the A5 cooling fan is?

Cooling efficiency is a combination of temperature differential and wiping velocity.

The original nozzle should have been designed to make use of the characteristics of the fan... in that the open area and distance from the nozzle tip to the work surface should be within the "sweet spot" for performance.

Making a nozzle with more than three times the open area should require a better fan (more flow and pressure?) unless the original nozzle opening was too small causing too great a wiping velocity or choking effect.

I would love to know more about this nozzle design for the cooling fan provided.

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!