Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

Can anyone tell what these lines are in print?

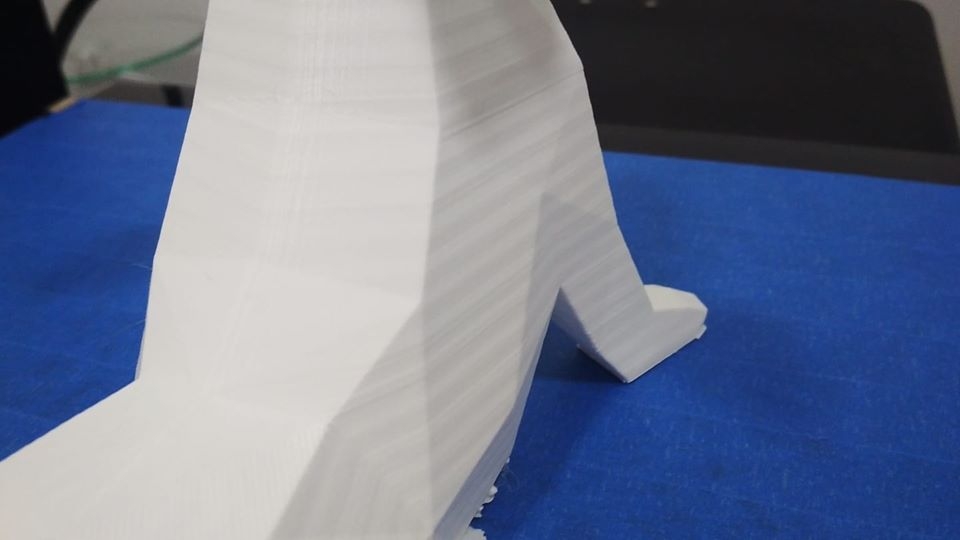

I am having a hard time getting more faithful results with my A5. I installed TL smoothers on the X and Y axes and I don't know if it's related to these lines. I also put a stabilizer for the Z axis spindle that moved unsteadily. I verified that the X-axis belt is tensioned correctly. Look the image. PLA white, 195° nozzle, 0,15 line height and 20 mm/s.

Thanks if anyone can help with this issue.

Thanks if anyone can help with this issue.

Comments

What I found was that my solid motor couplers were causing the linear rods to bow in and out as the gantry was moving! More so on the left where the x motor is than the right.

So I put back in my flexible coupler and I can say the bowing is down by 90% or so. The right side is still on the solid coupler, I might change it back.

In your case, you might look into swapping out you couplers.

Also, try doing a PID autotune for both your bed and hotend. Temperature fluctuations in your bed especially will cause it to physically move up and down during your print. You may have to modify your firmware to add PID control to the heat bed.

First I thank you for the information and help. Well, I have to say that I did a lot of work here to try to solve the problem and I still haven't found it. See the image below:

These are 20mm cubes with a single shell without bottom layer for test. Even with the lines, I can't feel the bumps when I run my finger across the surface. It's very subtle.

A pattern of lines is occurring every 4 mm. So I verified that it is exactly one complete revolution of the Z axis. I dismantled the entire mechanical system of all the axes. I noticed that on the Z axis the smooth bars and the threaded spindle are in perfect condition, without any warping.

I cleaned the entire system carefully by removing any older lubricants, dust particles or anything else that could influence the problem. I used the Da Hai Zhu video on YouTube as a reference

In addition I cleaned the entire hotend, checked the extruder gear and there is nothing wrong, but the lines insist on appearing.

Could it be that there was a problem with any of the engines? Regarding the PID, I honestly don't know exactly how to do this verification, because I'm not sure what it is. Is there a tutorial here? Is there any reset I can do to test? Or, could it be something in the Cura slicer?

I sincerely thank you for your help and keep trying to solve this problem.

Best,

Leo

Those cubes look better than the white model which had equal light and dark spacing

If you've gone back to the original stepper motor drivers, have you actually set the voltages of each one to the ideal voltage - info is somewhere in facebook group - maybe in the wiki as well

I've never had z banding, and never set PID which is temperature calibration - makes it more accurate - but that is not your issue - I'm thinking extrusion rate may be relevant - was way off in original firmware

Never had to fix this issue, so guessing now

https://jgaurorawiki.com/a5/stepper-drivers

Well, I agree with Samuel that the problem is still related to the mechanics of the Z axis. See, this problem happened after the installation of these "stabilizers" that I printed. I believe that by holding the tip of the threaded spindle, it forced something that was deformed. https://www.thingiverse.com/thing:3380716

As I had problems with some lines that insisted on appearing, I believed it was a problem because of the Z axis wobble. But I was certainly mistaken and ended up causing a bigger problem.

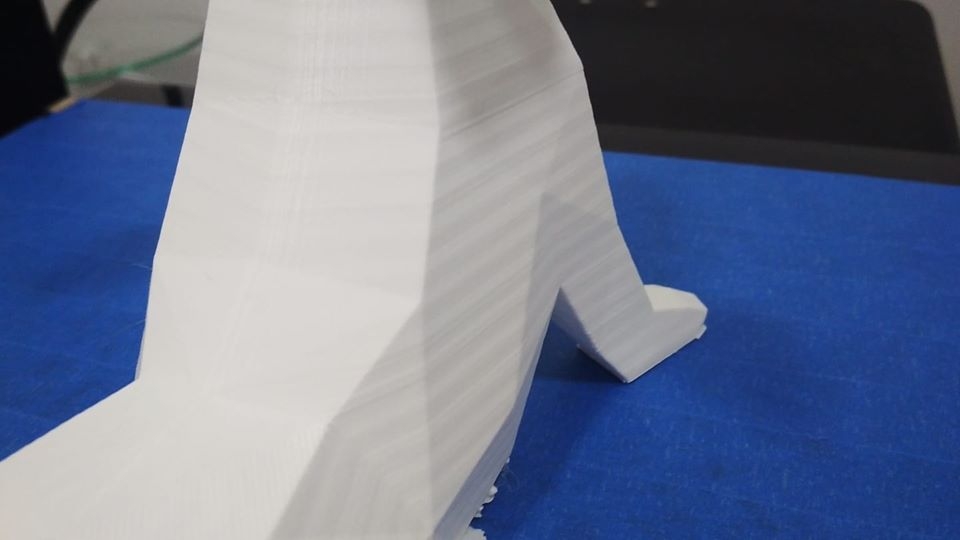

Here are the images of the couplers as you requested

I didn't notice any visual problems, but it is something very subtle that is causing the defect. The line appears every 4 mm exactly, which is equivalent to a complete turn of the Z axis. Taking advantage, both the screws and the flat bar are perfect, without any bent problem. I put them on a glass table and checked carefully that they are perfect. Now there are the couplers, motors or some problem that I didn't notice. This is driving me crazy!

Thanks a lot!

Thanks a lot!

Right now I'm printing some test models and I just noticed a loss of print quality, but I will make finer adjustments in the next few days to try to improve. The main problem with the lines that was extremely bad no longer occurs.

Thanks again for the help you gave me!

Best,

Leonardo from Brazil

Thanks for this post - i was suffering the same problem. i had already converted to an e3d v6 hotend so came to the conclusion is was heat related so had been playing around with thermistors etc trying to improve the print. You could feel the uneven walls too, but it was only visible in the white. in the black the print seemed ok, Anyways came across this post and checked my couplers, and mine were alot worse than yours. i had lots of spare new ones laying around so spent a few hours working through them trying to fine a a good set.. to be honest i think that is very rare to find. my only issue now is i got rid of the patterns, but now have very slight uneven walls.. so something else to look in to.

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!