Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

Inconsistent layer stacking

Gandy

Posts: 89🌟 Super Member 🌟

Gandy

Posts: 89🌟 Super Member 🌟

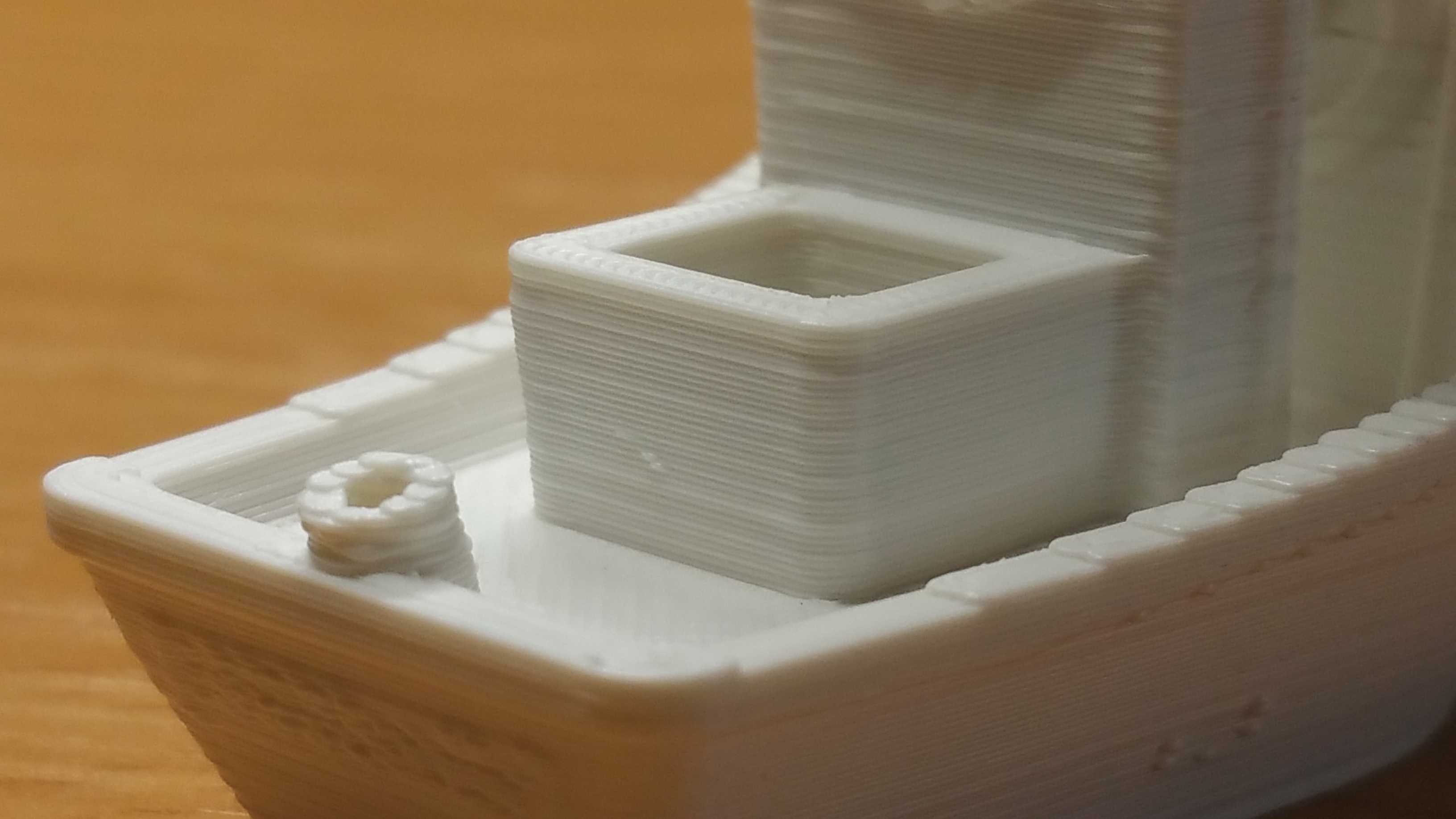

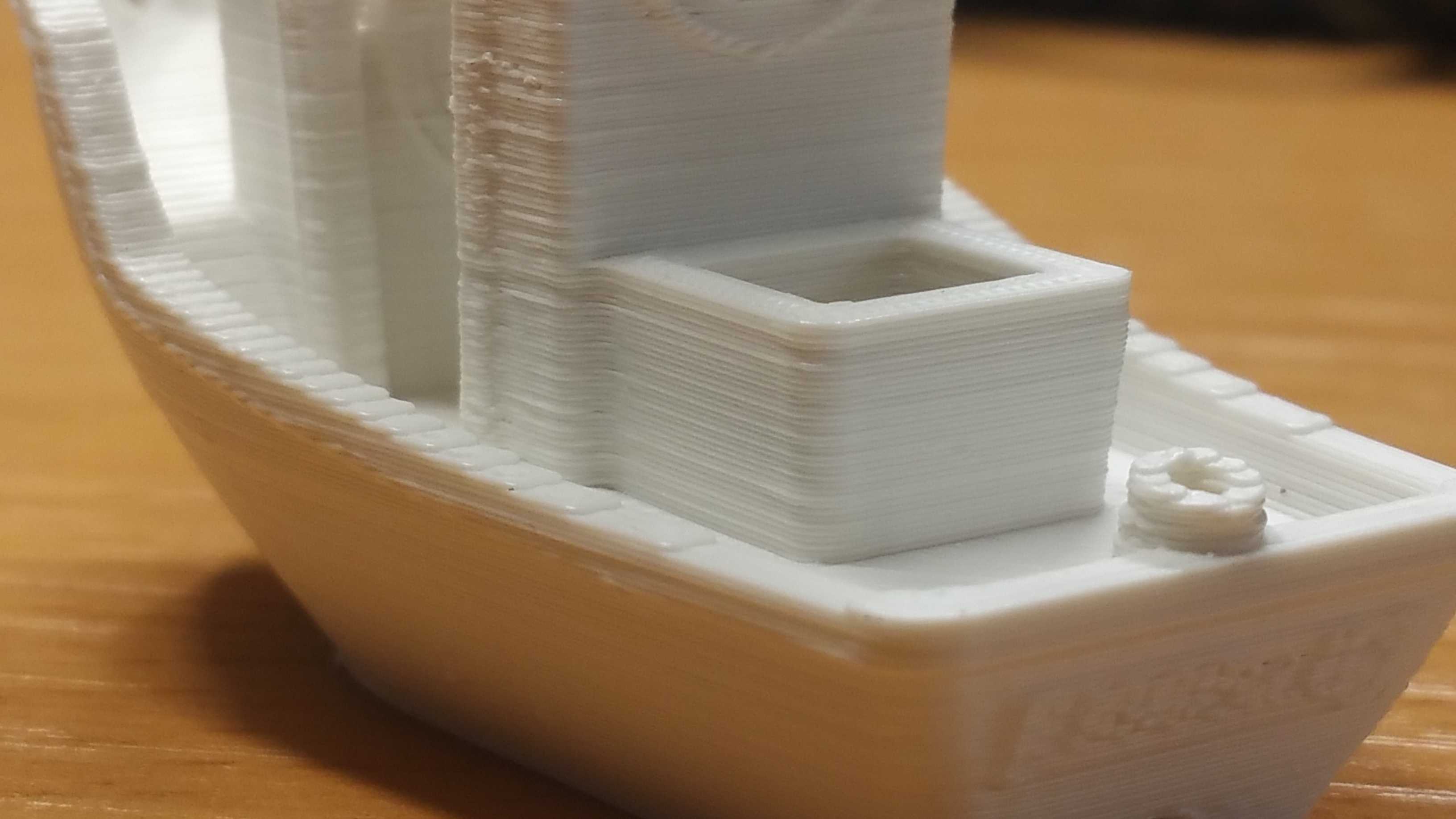

Prints come out more or less good on my A5, but there is a problem with the layer stacking I cannot get rid of. Being irregular, I cannot quite attribute it to z-axis wobbling, at least as a single cause:

The effect is visible on the 3D-Benchy I printed for reference (Cura 4.0.0, 0.2mm, 10% infill, 100%fan with BlowHard3000; see attached cura-settings.txt). I'm using Marlin bugfix-1.1.x with S-Curve-Acceleration, Linear Advance and Junction-Deviation (though the layer stacking loocked the same with both the stock FW and Marlin 1.1.8 w/out the extra features):

The filament I'm using is extrudr PLA NX2 with consistent diameter. I noticed however, that the extruder wheel imprints itself quite noticibly onto the filament,

transforming it from O-shape to D-shape. The more ridig e-sun filament shipped with the printer didn't show this effect as much, but the layer consistency wasn't better, either. I did pay extra attention to extruder calibration.

Over the last few months, I've applied a few mods to my printer to aim for better mechanical stability:

- Removed the spool holder from the chassis to keep the spool from picking up oscillations from the x-axis movement and feeding it back to the z-gantry.

- Placed the whole printer on simple vibration dampers.

- Replaced the bed springs with fixed nylon spacers (with internal threading to have a snug fit on the bed screws), using a BL-Touch for leveling.

While the first two helped with ghosting, the latter showed no obvious effects, neither for better nor worse. Unfortunately I only started printing 3D-Benchies after all those mods, so I have no objects that can be compared 1:1.

Since I installed TMC2208 I could hear the slightest grinding noise during movements but moving both the bed and the x-sledge by hand appears to be smooth enough. Nevertheless, I've just odered the set of higher quality bearings from AliExpress. Replacing the bearings will be a good opportunity to check the lead screws and the couplers.

Any suggestion on what else I could do to improve layer consistency is highly appreciated. Or is the quality visible on my 3D-Benchy already the best I could expect? What is the quality I can reach with the A5, can someone please post reference fotos?

Cheers,

Andy.

Comments

I decided to actually do it I noticed my average extruded was 105.6mm instead of 100. To do this pull out the bowden from the hot end, use flush cutters to snip filament at end of tube. Extrude 100mm snip flush and repeat a min of 2 more times.

Measure and get average of your 3+ lengths. And do some math and edit firmware.

Math

Get average (in my case 105.6)

Get current firmware steps (typically 100)

Firmware steps x 100 = 10000

10000 / average (105.6) = 94.69

Change your firmware steps to be the number you got in my case 94.69. upload firmware and test/repeat until happy.

Once you are done calibrating make sure the tube fits all the way down again.

---

Second thing is cura has layer widths at .4 instead of always suggested .5. change those. Then once you do that take a calibration cube, 0 top/bottom layers 1 wall (at layer width, if above it will be .5). Print that and measure the wall width. If it's at .5 perfect. If it's not the look up how to adjust the flow/extrusion multiplier. Since mine was good I didn't need to adjust.

---

Make sure you also do a pid test on your hotend. Since you will be in the firmware it's easy to do it now.

---

Lastly calibration cube x/y esteps. There are lots of Tut's on how to do this. Not as complicated as the first thing but still do it

Once you do all of this and you want some help on a cura profile I do have a jgaurora A5 Reddit post with a profile there. It's not updated with my newest settings but I suggest changing layer width to .5

M301 P35.30 I4.35 D71.57 ;Firmware defaultM301 P63.63 I7.13 D142.03 ;with fan offM301 P67.55 I7.50 D152.17 ;with fan @ 100%The oil can be add on the filament, the filament transferes that oil in the hotend. I had very good results with DRY Lube PTFE spray directly in the throat. It leaves no oil which can set itself up on the nozzle. Max temp should be around 280°C PTFE oil has a max temp of 250°C and canona oil I realy dont know but it is for sure lower.

Mostly it helps alot with PLA problems on all metal throats, it helps a bit on PTFE throats.

Check your couplers on Z if they are centrical, @itisnot_me for example had very bad once, it can affect the layers in the lower part of the print because you get iregular preasure on the linear guides.

I recommend the BGM extruder to improve the print quality a lot. Not important if it is the original or the clone. But with a other motor than the standard one. (BGM needs 3 times higher speed), the standard motor gets hot quick and skips steps it was very hard to finde out that the motor skips steps on the extruder.

By the way, your print looks for me overextruded. Try to lower the multiplyer and start your testprints maybe near underextruding (0.95 in S3D I dont know how its in cura) and set it up after and after. In S3D I end up using the automode for layer wdth because the fix set up end up sometimes in seperate outer and inner walls at thin walls.

100% fan is not always a solution, I tryed it out on a good print setting which effect it has and found out that to much fan is contra productive. To less fan is not so bad than to much fan. But that ofcause is also different with differend build in fans, which makes help on costume systems quite hard. Every printer reacts differend, depending what tuning it has. But one is sure, the standard cause of problems doesnt fit to a tuned printer and the problems are mostly caused on wrong slicer settings. That I always found out. My problems where caused always on that and I always ment it where the hardware. (saves a lot of time with problem solving) Better to reset to default and beginn setting up a setting from beginning. One wrong setting and 1000 other settings which correct it can end in a good result but in the end it effects the print with a other model you want to print. Default setup and little changes end up much better. (was also a long time for me to find out.)

Hope it helps you. Dont change to much in the firmware, always save your last firmware settings to be able to go back!

And if its to late, better go back to default and change not to much at once. One change, one test and so on.

Firstly here is the most updated profile I use. It has been tested on other printers with success. I have tuned in the supports and tree supports along with a bunch of other settings. (if you do not have 2208 drivers then up your retraction) https://mega.nz/#!HHxX2ACZ!SYBKPyJluKJrJT-mklifGhVE8dY1MUxO9Fa8q6uU9Qo

So I went down the road more on this wobble issue and I found a very real problem. My coupler's were not concentric. I have since bought new ones and printed more tests to get to this.

The only difference in the above was new couplers. Same exact gcode. I still have bent rods but it still is way better.

You see how bad the one coupler is. Even worse is that they did not even provide the screws in the back holes to tighten onto the rod and shaft. This just shows poor caring about the printer.

The I changed the nozzle and got this.

As you can see it got slightly better. I still might change the rods in the future but the prints are much better.

As I am a mechanical engineer I have more that 15 Years of welding practice. My first welding machine was a Fronius Compact 450 out of the 80s maybe ending 70s.

It had a one weel transfere weel like the JG has. It works but you need much preasure what can leave a deformed welding wire or a unregular transfere of it. But ofcause it worked very well.

Now I have a Fronius TPS 400i Pulse PMC so very high end, it has 2 double transfere rolls where all 4 rolls are pushing the wire. Less force is need and thers simply nothing that can stop the wire. 100% perfect wire transfere.

Those systems are similar to a 3D printer filament extruder. Wierd is that the JG has a straight transfere roll. Normaly when you weld MIG Aluminium its a good comparison to a filament in a printer, its weak. You would never ever use a V roll in combination with a flat roll for Alu in a welder. Why do they use even 2 flat rolls in a printer? Only because its cheap to produce but it deforms the filament.

So as for aluminium there are preformed rolls for the welding machine and the same I would use in a printer. For sure there will come more 2 double roll extruder in the future, but for now thers a single roll system (BGM) where both rolls transfere the filament. I only recommend using such a system if you ever want good filament transfere. The other systems like the original JG extruder are simply to play around and for nothing. Every other work isnt important at all, it will only change a very little but the biggest problem will always be the extruder and the motor of it.

When you change the system to a BGM style system, always change the original motor to, its also crap. (recommend that with all the motors exapt on Z there its not so important.

Skipped steps are not your problem, those you would mostly have on the BGM extruder and the original motor. Skipped steps would mostly happen when you have very very fast retractions and looks like underextrusions or over extrusions on the beginning of a layer. Those doesnt effect the whole layer at all.

P.S. Dont use so much oil that it drips out, its not need at all. One drop of oil in the coldend is enough, or a little on the filament.

Hope it helps.

My english writing mistakes are as always for free XD

I didnt know this one but it seems to be like the other BGMs only with a smaler size. Must work to ofcause, it has the same gear in it.

@Gandy

It is not garantied that it will solve your problem but one thing is sure, it will boost the print quality and maybe solve your problem to.

For me its totaly clear that the A5 is a bowden constructed printer. And when the system is working good, it can deliver same results like a DD. To have a DD is not a solution for everything. People that have DD systems want a bowden system and the other way round, its always funny but in the end, it depends how the systems work. When there is a good bowden system, it cant be beaten by a DD system. A DD on a A5 ends up in losing print high, more weight on the X axes and needs much higher forces for acceleration on X what ends up in a hot X stepper motor.

But in the end everybody must know itself what he wants.

In the end it might well be that the grass is greener on the other side after all, and a good extruder might have done the trick. Right now I am under the impression things can only improve by removing the bowden entirely.

Our 15000 printer in the company also has a double bowden system, thats working to.

@itisnot_me

Maybe, you have to try it. But i would move it up, I can send you my easy solution on that.

Left is new extruder

Per all the rest of the prints the wobble is pretty consistent/baked not really random.

Here is a video of the rods at the top.

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!