Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

Marlin Firmware and bed size settings

jpasqua

Posts: 9Member

jpasqua

Posts: 9Member

I'm a little confused about the bed size for the A5. I'm hoping someone can confirm my interpretaton.

The specs say it is 305x305mm. The Marlin code agrees:

* The left 5 mm of the physical build plate won't be used unless the gcode specifies negative X coordinates

* The back 5 mm of the physical build plate won't be used

* The 314x314 numbers are just wrong - it's closer to 310x310

I'm making a magnetic build plate and removable spring steel sheet to replace the black diamond glass. I plan to make the spring steel sheet cover the entire build plate of 310x310, and try to find a source of a buildtak-like material that I can get in this size.

The specs say it is 305x305mm. The Marlin code agrees:

#define X_BED_SIZE 305

#define Y_BED_SIZE 305

but also specifies that:

* The actual printable area is 310 in X and 305 in ybut also specifies that:

#define X_MIN_POS -5 // thanks DaHai.

#define Y_MIN_POS 0

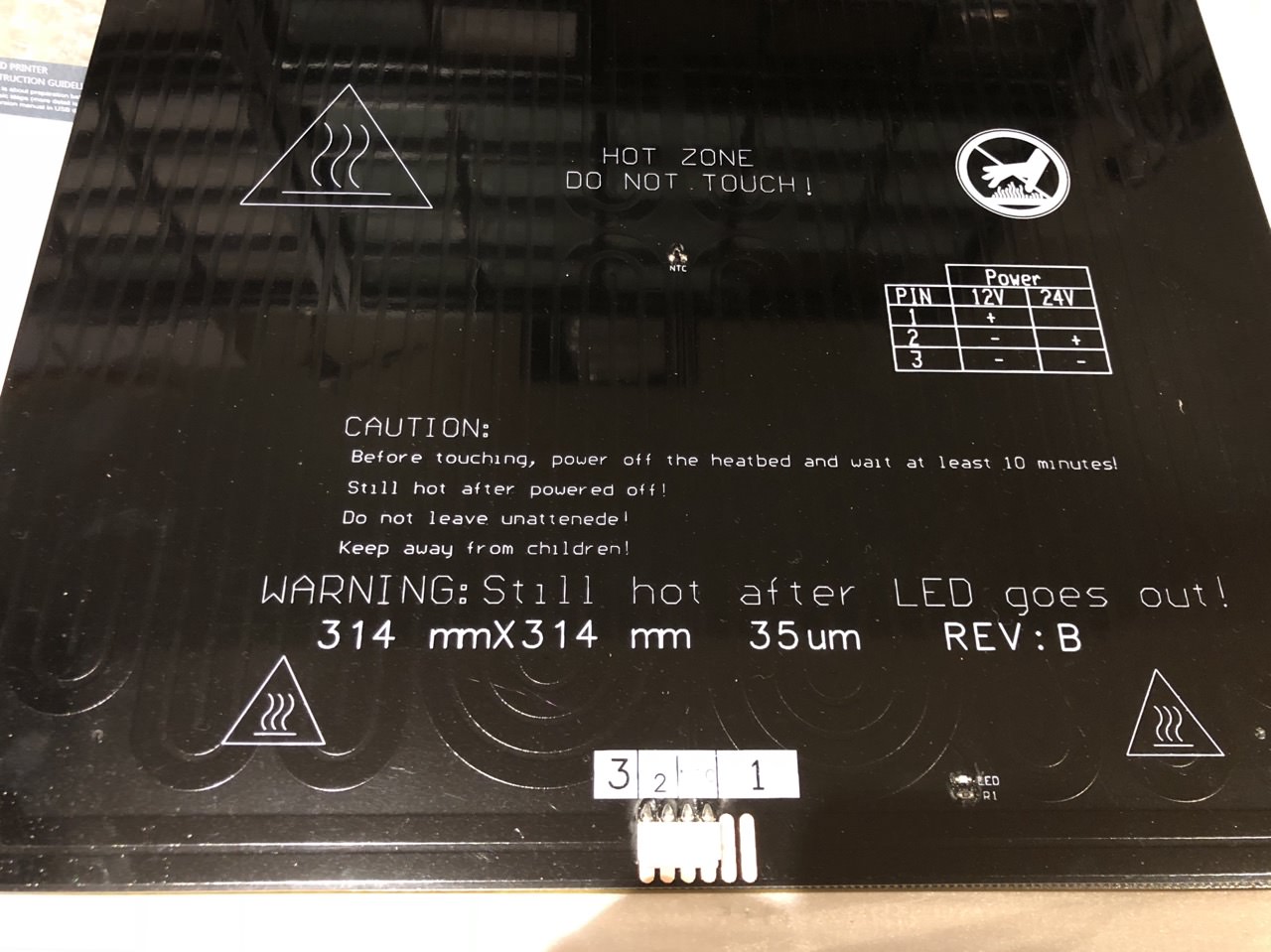

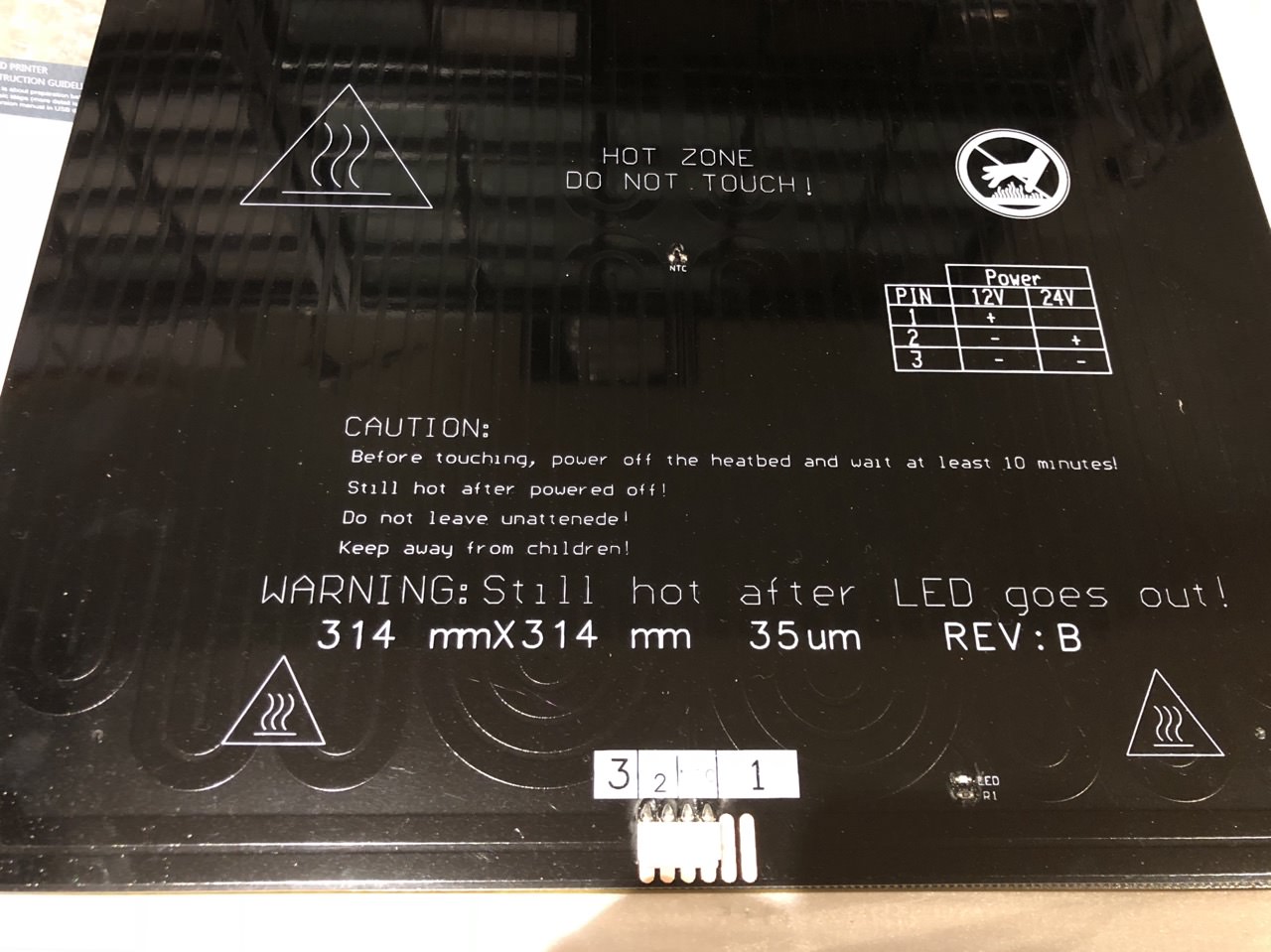

The back of the heated bed says it is 314x314mm (see image). When I measure it, it is closer to 310x310.

Based on this, I am guessing that:

The back of the heated bed says it is 314x314mm (see image). When I measure it, it is closer to 310x310.

Based on this, I am guessing that:

* The left 5 mm of the physical build plate won't be used unless the gcode specifies negative X coordinates

* The back 5 mm of the physical build plate won't be used

* The 314x314 numbers are just wrong - it's closer to 310x310

I'm making a magnetic build plate and removable spring steel sheet to replace the black diamond glass. I plan to make the spring steel sheet cover the entire build plate of 310x310, and try to find a source of a buildtak-like material that I can get in this size.

Comments

And I'm a PrintBite Evangelist. Prints stick like superglue when hot and slide off effortlessly when cold. No bending, chiseling or scraping. Used it for over 2 years and its not worn out yet.

https://flex3drive.com/printbite/

Hi, I thought that this "black diamond platform" is actually a "wanted" feature..

Why do you want to change it?

- DaHai: And I'm a PrintBite Evangelist. Prints stick like superglue when hot and slide off effortlessly when cold. No bending, chiseling or scraping. Used it for over 2 years and its not worn out yet.

https://flex3drive.com/printbite/Does the provided "black diamond platform" have exactly that same purpose, why wanting to use something else?

PS: I don't know how to cite comments... If anyone can tell me..

The black diamond coating works reasonably well, it’s just very sensitive to oils or fingerprints. If cleaned properly prints stick quite well (and are easy to remove) but perhaps not quite as firmly as with something like PEI. or printbite

I probably end up doing the same!

So your "flexible" steel sheet will rest directly on the heat bed without glass?

Would you posts some pics at the end of your setup?

https://www.thingiverse.com/thing:2777120

I thought about pics later on when you will finish your setup..

I'm not in a hurry..

BTW, thanks for the link...

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!