Please note: the forum is closed.

No new user registrations are accepted. For more info, please click here.

No new user registrations are accepted. For more info, please click here.

Advanced Nozzle Priming

Hello,

Cleaning the nozzle is important. The filament remaining in the hot end tends to denature when it is not moved. This leads to problems in printing quality. Especially important is the filament adhesion at the first layer. So that good filament quality is available for the first layer, it makes sense to get rid of the remaining filament remnants of the last print in the hot end.

For this I have always used the "Skirt" function of the Slicer program.

It sometimes happens that scraps of the skirt filament are pulled into the working area.

In addition, the amount of filament used to clean the nozzle varies considerably. For very small objects, the cleaning is then incomplete. For large print objects, filament in the skirt is wasted.

Cleaning the nozzle is important. The filament remaining in the hot end tends to denature when it is not moved. This leads to problems in printing quality. Especially important is the filament adhesion at the first layer. So that good filament quality is available for the first layer, it makes sense to get rid of the remaining filament remnants of the last print in the hot end.

For this I have always used the "Skirt" function of the Slicer program.

It sometimes happens that scraps of the skirt filament are pulled into the working area.

In addition, the amount of filament used to clean the nozzle varies considerably. For very small objects, the cleaning is then incomplete. For large print objects, filament in the skirt is wasted.

In order to avoid the mentioned disadvantages, I thought and came to this conclusion.

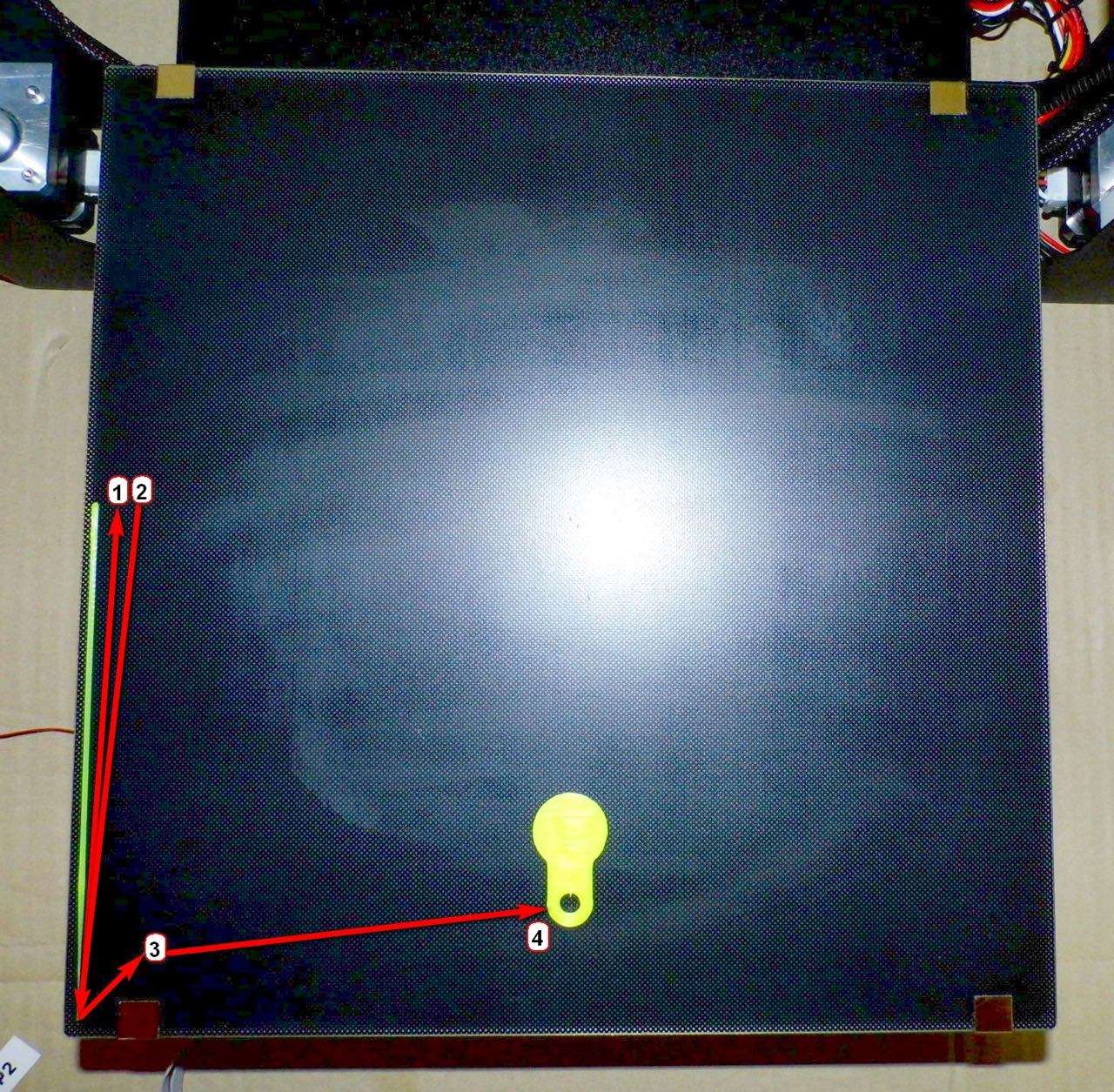

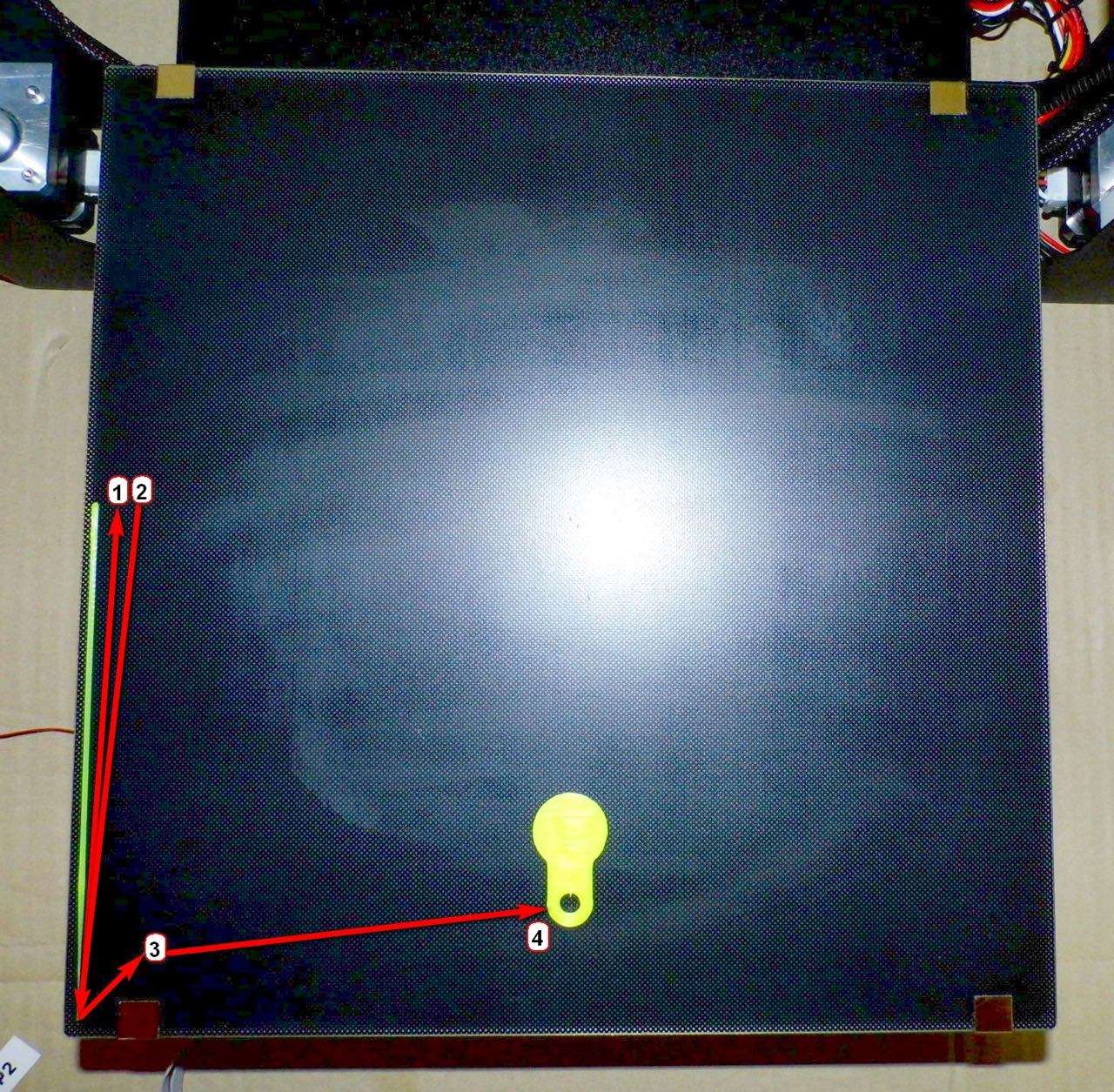

- In START-GCODE, a precisely defined amount of filament is output at the edge of the print bed, which is independent of the print object.

- Through coordinated travel paths, filament residues adhering to the nozzle are scraped off as far as possible. The target work area should not be contaminated with filament residues.

This is an example for Simplify3D:

;STARTING GCODE START ------------------------<br>; Avoid special characters + umlauts<br>;------------------------------------------------------------------------------------------------<br>M140 S[bed1_temperature] ;Set Bed Temperature + Continue <br>M109 S190 ;Prepare Hotend for Homing Z. Set Hotend Temp 190C + WAIT<br>G28 ;Home X Y Z Axis<br>M109 S[extruder0_temperature] ;Set Hotend Temperature + Wait <br>G92 E0 ;Reset Extruder<br>;------------------------------------------------------------------------------------------------<br>; START CLEANING WITHOUT SKIRT<br>M107 ;Fan off<br>G21 ;Metric<br>G90 ;Absolute Coordinates<br>G0 X1 Y1 Z0.20 F5000 ;Goto Clean start position <br>G92 E0 ;Reset Extruder<br>G1 X1 Y160 E50 F500 ;Extrude 50mm Filament<br>G90 ;Absolute Coordinates<br>G0 X1 Y1 Z0.40 F500 ;Move from Back to front<br>G0 X20 Y20 Z0.15 F200 ;Sheer waste <br>G0 X20 Y20 Z5 F200 ;LIFT Z to 5mm while waiting for Start Print Temperature<br>G92 E0 ;Reset Extruder<br>; END CLEANING WITHOUT SKIRT<br>;----------------------------------------------------------------------------------------------------<br>M109 S185 B250 F1 ;Autotemp on 185...250C (For PLA only)<br>;STARTING GCODE END --------------------------<br><div><br></div><div><br></div><div><br></div><div><span>At the end

of printing, it is pleasant to see the print head move out of the way

and the print bed come forward to release the print result. I have installed this function in the <b>END-GCODE</b>.<br></span></div><div><img alt="" src="https://jgmakerforum.com/uploads/editor/jq/xxd3kcslwein.jpg" title="Image: https://jgmakerforum.com/uploads/editor/jq/xxd3kcslwein.jpg"><br></div><div><br></div><div><br></div><div><span>;<code>ENDING GCODE START -------------------------<br>M107 ;Fan off<br>G92 E0 ;Reset Extruder<br>G1 X0 Y300 Z320 E-3 F4000 ;Quick move Nozzle away while retracting 3mm Filament<br>M104 S0 ;Turn hotend off<br>M140 S0 ;Turn heatbed off<br>M109 R45 ;Cooldown and wait to reach 45C<br>M84 ;Disable steppers <br>M81 ;Power off<br>;ENDING GCODE END -------------------------Better ideas and suggestions for improvement are welcome.

Greetings

AETEK

Greetings

AETEK

Thanked by 1Samuel Pinches

Post edited by AETEK on

Comments

Gracias por tus sugerencias.

Saludos.

Luis

G21 ;set units to millimetres

G90 ;set to absolute positioning

M106 S0 ;set fan speed to zero (turned off)

G28 ;home all axis

M420 S1 ;turn on mesh bed levelling if enabled in firmware

G92 E0 ;zero the extruded length

G1 Z1 F1000 ;move up slightly

G1 X60.0 Z0 E9.0 F1000.0;intro line

G1 X100.0 E21.5 F1000.0 ;continue line

G92 E0 ;zero the extruded length again

G1 F1500 E0

G1 F1800 X146.676 Y145.928 E0.0103

;Generated with Cura_SteamEngine 3.5.1

>M140 S60

>M105

>M190 S60

>M104 S210

>M105

>M109 S210

>M82 ;absolute extrusion mode

G21 ; set units to mm

G90 ; set to absolute positioning

M106 S0 ; set fan speed to zero (turning off)

G28 ; home all axis

M420 S1 ; enable the mesh correction

G1 Z15.0 F6000 ; move up 15mm at 6000mm/min

G92 E0 ; reset extruder length to zero

G1 X0.0 Y0.0 F1000.0 ; go to edge of print area

;G1 Z0.20 F1000.0 ; go to Start Z position

G1 X60.0 Z0 E9.0 F1000.0 ; start intro line

G1 X100.0 E21.5 F1000.0 ; finish intro line

;G1 Z5 F1000 ; nozzle raising to take it off from the printed filament (to test)

G1 E20.5 F1000 ; retract 1mm

G92 E0.0 ; reset extruder distance position

>G92 E0

>G1 F1500 E-6.5

Howdy, Stranger!

RegisterIt looks like you've been lurking for a while.

If you register, we will remember what you have read and notify you about new comments. You will also be able to participate in discussions.

So if you'd like to get involved, register for an account, it'll only take you a minute!